Wheel Spacers have a clear role to play in the modification of off-road vehicles, and there are only a few outstanding off-road vehicles, such as Land Cruiser, Defender, and others being among the best off-road vehicles. The Mercedes-Benz G-Class, one of the 2022 Top 10 best 4x4s and off-road cars, is an off-road powerhouse, with a rigid military-style design that brings together a high degree of practicality and luxury, favored by military dignitaries and celebrities alike. If you would like to own a G-Class for off-road use or if you already own a G-Class, modifying and upgrading your G-Class will enhance the vehicle’s performance to the limit, with a set of wheel spacers of the right thickness is fitted to give a significant boost in stability and appearance.

Wheel spacers are often a polarising topic, with some people resisting criticism of wheel spacers and consumers who use them, and others using them rationally and safely and enjoying the benefits they bring to driving, so what BONOSS advocates are choosing the right wheel spacers for your car. A large part of the examples with wheel spacers failing are caused by users who install them incorrectly or moreover according to wrong guidelines, rather than by the wheel spacers themselves. Instead of blindly following public opinion, it is better to take a look at the overview of wheel spacers and the complete installation process before deciding whether to buy wheel spacers or not.

What Wheel Spacers Do?

Off-road vehicles require high ground clearance to improve passing over obstructed surfaces and to avoid damage to the vehicle chassis from obstacles. Ground clearance (Ride height) refers to “The amount of space between the base of an automobile tire and the lowest point of the automobile (typically the axle)”. There are three ways to adjust ground clearance, including buying larger tires, installing coil spring spacers, and buying a suspension lift kit. all three methods will ultimately help you to achieve a change in the vertical height of the vehicle, but the change in ground clearance also brings about a change in lateral stability.

As far as our common sense knows, sports cars are designed with a low center of gravity and a streamlined body, the important reason being that a streamlined body minimizes the impact of airflow on the speed at high speeds and the center of gravity is lowered to help the vehicle achieve better handling, while the original ground clearance of the G-Class is already higher, in addition to this, the body weight is also heavier than the average car. In contrast, cornering maneuvers are more likely to produce a shift and tipping of the center of gravity, which is of course unlikely in the stock set-up but also causes drivers to be wary of the shift. Although high-speed cornering is mostly seen in racing games. However, ground clearance has been shown to be an important factor in the car’s handling.

Widening the track improves the driving stability of vehicles with high ground clearance, either by changing the length of the axle or correcting the offset, but replacing the axle is obviously a complicated solution for owners who want to go off-road occasionally. Replacing the rims with negative offsets or purchasing a set of wheel spacers to push the rims outwards is the simplest solution. The ideal negative offset for off-roading will lead you to buy a set of expensive alloy rims which have a smaller backspacing and negative offset, which will prevent the new rim from rubbing against the suspension or using wheel spacers to push the rim outwards against the suspension. The reason for flushing the fenders is to prevent mud from being splashed onto the car on muddy roads. Buying a set of wheel spacers will increase the backspacing and thus push the rim outwards, adjusting the offset of the rim while retaining the OE rims, using wheel spacers is a cost-effective off-road option.

Back Spacing and Offset are two positively related values, with Back Spacing being “The distance from the back of the mounting pad to the back lip of the wheel.” The higher the Back Spacing value, the higher the offset value.

What Wheel Spacers Do Mercedes-Benz G-Class Need?

Data: When choosing to buy Mercedes-Benz G-Class wheel spacers, you need to check the PCD and CB data of the vehicle, the data of the same model of different years may also be different. BONOSS wheel spacers have two types: Slip-on and Bolt-on wheel spacers. Slip-on wheel spacers use extended lug bolts to fasten the rims. Bolt-on wheel spacers are attached to the hub using the lug bolts that come with the wheel spacers and the rims are attached using the OE lug bolts that come with the car. Take a example of 2022 Mercedes-Benz G550, PCD:5×130, CB:84.1, Thread Size:14×1.5, Length:45mm. Information on the above can be obtained by contacting Customer Services.

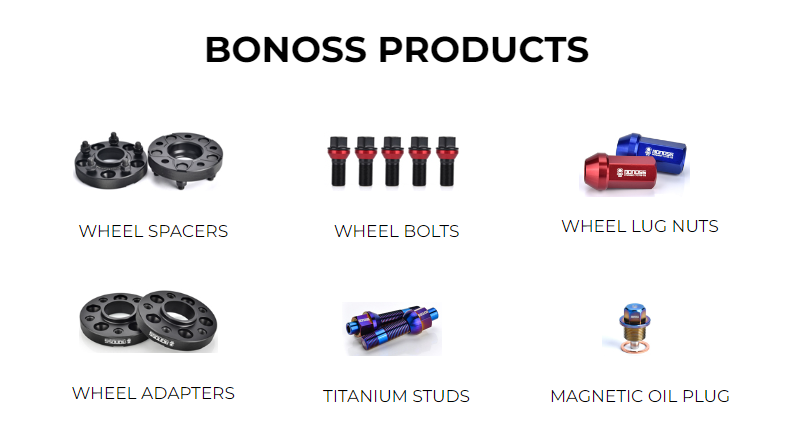

Brands: The most famous brands in the wheel spacers market nowadays are H&R, BONOSS, Eibach, etc. These companies clearly support the wheel spacers they produce, while providing a considerable number of years of warranty service. Most wheel spacers claim to be safe and high performance, but only a few wheel spacers brands will accept safety certification from the authoritative SGS and TÜV testing institutes. Click here to see the TÜV and SGS test reports for BONOSS.

Price: When the word “CHEAP” appears on the shopping page of wheel spacers, you can turn around and leave. The most common thing on the market is cheap wheel spacers. The price of high-quality 6061-T6 and 7075-T6 aluminum alloys does not come with a cheap price tag. Each BONOSS wheel spacer is laser-engraved with the name of the material used to manufacture it.

Materials: The primary material used in wheel spacers is aluminum alloy 6061-T6 or 7075-T6. When selecting a safe wheel spacer, it is important to understand tensile strength, yield strength, and elongation at break, these characteristics usually represent the upper limit of the stress that can be applied. Tensile strength is the maximum tensile load that a material can withstand before breaking and yield strength is the strength at which deformation changes from elastic to plastic deformation. Below are material data for 606-T6 and 7075-T6, with 7075-T6 aluminum alloy being the highest performance material for the manufacture of wheel spacers.

| 6061 | 6061-T6 | 7075-T6 | |

|---|---|---|---|

| Ultimate Tensile Strength | 18000 psi (125 Mpa) | 42000-45000 psi (300-310 Mpa) | 74000-78000 psi (510-572 Mpa) |

| Tensile Yield Strength | 8000 psi (55 Mpa) | 35000-40000 psi (241-275 Mpa) | 63000-69000 psi (434-503 Mpa) |

| Fatigue Strength | 8800 psi (61 Mpa) | 14000 psi (96 Mpa) | 23000 psi (160 Mpa) |

| Hardness (Brinell) | 33 | 93 | 150 |

Processing: When processing with 6061-T6 or 7075-T6 materials, the different processes used for forging processing also give different properties to the raw material, which are mainly divided into casting and forging processing methods. Forged aluminum wheel spacers are made from solid billets, which are subjected to continuous high pressure to form them. In particular, forged wheel spacers are one-piece formed products. Due to the continuous stress cycles and deformation processes, forged wheel spacers become hard and tough and their properties are greatly enhanced. Casting dissolves aluminum alloy material through high temperatures and the dissolved liquid metal is poured into a fixed mold and then cooled and shaped, although it is also formed in one piece, it is not as strong structurally as the forged product. Forged wheel spacers achieve the same structural integrity with less material than casting wheel spacers. In addition, forged wheel spacers are stronger than cast wheel spacers, given the strength of the equipment required to manufacture them. Structural damage to wheel spacers can be caused by the presence of air pockets in the cast product.

Forged aluminum shavings are thin and slender and can be stretched for a long time without breaking. This is due to the toughness of forged wheel spacers. This is strong evidence of precision manufacturing and the high toughness of forged aluminum. Cast aluminum scrap, on the other hand, is soft and granular and can be easily broken if stretched long enough. This is because the grain structure of cast wheel spacers is more random, resulting in reduced strength.

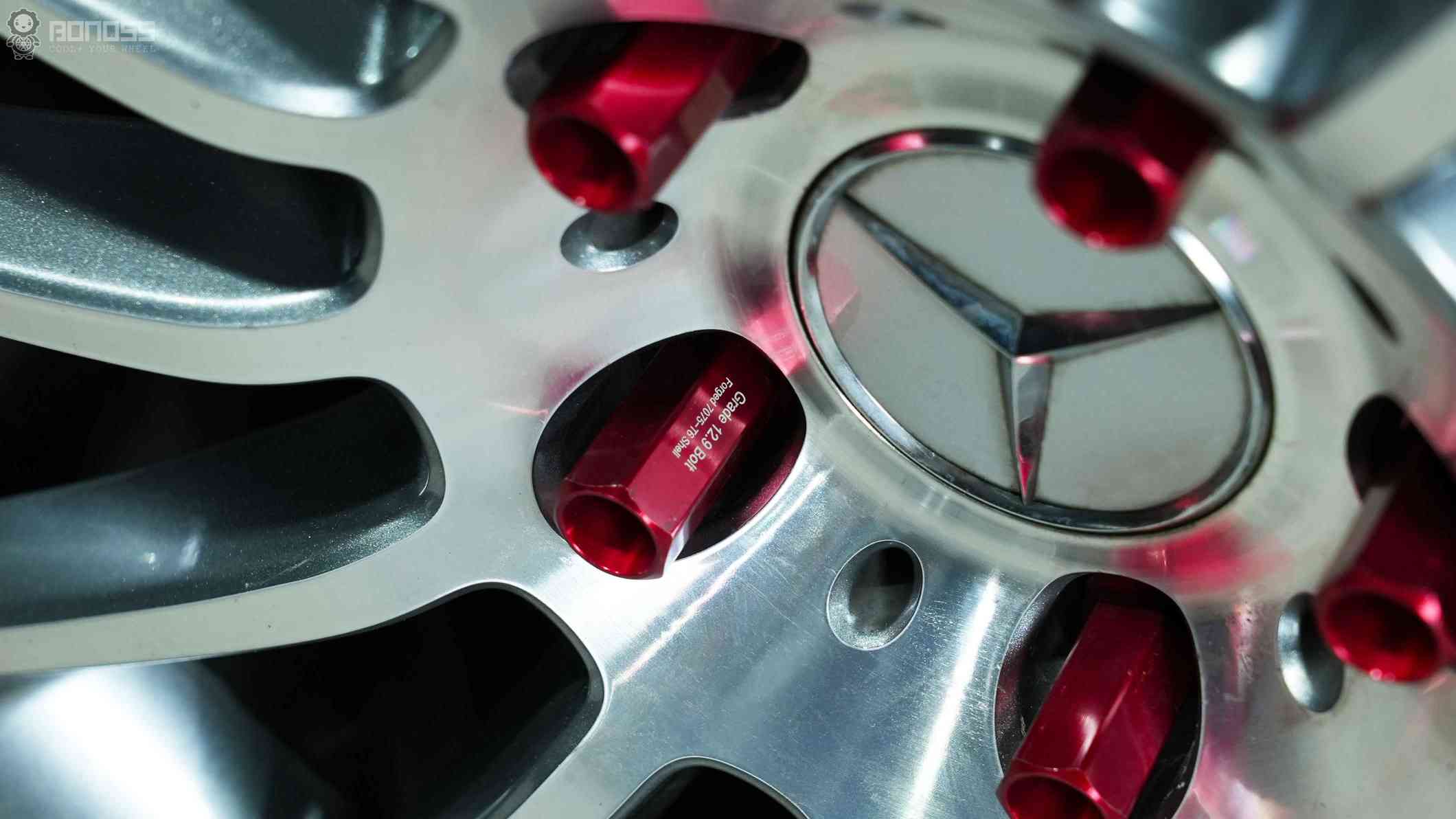

Lug Bolts: Lug Bolts are divided into grades according to performance and are classified into more than 10 grades such as 3.6/4.6/4.8/5.6/6.8/8.8/9.8/10.9/12.9, etc. Bolts above grade 8.8 are made of low carbon alloy steel or medium carbon steel and are heat treated (quenched and tempered) and are commonly referred to as high strength bolts, while the rest are commonly referred to as ordinary bolts. BONOSS uses lug bolts of grade 10.9 and 12.9, with grade 12.9 bolts being very popular and considered to be the safest bolts. The same technology is used for lug bolts as for wheel spacers, and forged lug bolts are the ideal choice. Click here to know more about BONOSS Lug bolts.

Rust Protection: The common surface treatment for BONOSS wheel spacers is hard anodizing, while lug bolts and lug nuts are treated with a Dacromet finish and electrodeposition coating. The reason for using these two methods of rust protection is that the Dacromet finish provides excellent protection for the wheel bolts. It is 7 to 10 times better than conventional galvanizing. The neutral salt spray test can last for over 500 hours or more, far better than galvanizing. The Dacromet treatment performs well in automotive wheel bolts because it penetrates into the tight joints of the workpiece to form a rust-proof coating. The electrodeposition coating, on the other hand, has good corrosion resistance and improves the rust resistance of wheel bolts. In addition, it has excellent resistance to extreme environments such as water and sunlight. It can coat wheel bolts evenly, thus providing better surface quality.

Warranty: For big trusted brands, a reasonable warranty period should be provided, please pay attention to the warranty period before purchasing, please do not buy products without a warranty period.

How to Install Wheel Spacers Properly?

In the case of the 2022 Mercedes-Benz G-Class, which has lug bolts for the rims, we need to use the BONOSS BLA series wheel spacers for installation. To fix the vehicle with the lug bolts, proceed as follows.

- Stop the vehicle and ensure that it is in first or P gear and that the handbrake or electronic handbrake is on.

- Loosen the lug bolts on the front wheel side in a diagonal sequence using crossed spanners, but do not remove them completely.

- Placing jack stands to support each end of the car would be a better safety measure.

- Remove all lug bolts on the front wheel side using a crossed spanner. Remove the rim from the front wheel.

- Look at the wheel assembly for stains or rust, you can use a degreaser to clean the brake discs. Remove any rust and dirt from the wheel hub with a rag. Widen the entire surface to ensure it is smooth. This is because all of that surface may cause the wheel spacer to not fit perfectly with the hub.

- Match the holes in the wheel spacer to the bolt holes in the car. You can check that the spacer is firmly seated and flush with the wheel by gently shaking it. Start using a torque spanner to fix the spacer with the lug bolts supplied with the wheel spacers.

- Install the front rim and then reinstall the OE lug bolts. Use a crossed spanner to tighten them on the wheel spacers (install in diagonal order). Make sure they are secure but do not tighten the lug nuts completely.

- Remove the jack stands. Slowly lower the car until the tires fully touch the ground and remove the jack.

Use a torque spanner to tighten the lug bolts to the specified torque. Always tighten them in a diagonal sequence. This will ensure that the lug bolts work. - Threads are correctly and securely seated. (Do not use an impact spanner)

- Repeat the above steps.

- After installing the full-wheel spacers, drive slowly back and forth, making sure the rims are turned a few times. Then turn off the engine and re-tighten each lug bolt with a torque spanner to the specified torque value. Ensure that all lug bolts are in good working order.

BONOSS recommends checking the use of the wheel spacers every 6 months and checking the operation of the vehicle to ensure safe driving.

Can Wheel Spacers Cause Vibration?

Many customers are concerned about whether wheel spacers will cause vibrations. In fact, wheel spacers themselves do not cause vibrations; they simply increase the track of the wheels. In this way, the weight of your vehicle is evenly distributed over all the rims, thus improving the comfort of the vehicle’s handling. They are widely used to correct existing undue deflection situations in the rims or to clear clearance problems with larger brake kits. In any case, a number of causes may contribute to vibration.

- Use cheap cast wheel spacers. If you use low-quality wheel spacers, your wheels can fall off or be lost. Never use cheap spacers!

- Use lug-centric wheel spacers, not on the hub. Due to the lack of support from the hub, the rims may sometimes be unbalanced due to some violent impacts.

- The rim may not be fitted to the spacer correctly. Double-check that the lug bolts are long enough to hold the rim in place to prevent it from coming loose.

Use hub-centric spacers instead of lug-centric spacers. Hub-centric wheel spacers provide a better support and stability system. They are designed to create a tight connection between the rim and the hub, ensuring that the hub carries the weight of the vehicle, rather than the lug bolts. Most of the disadvantages people associate with wheel spacers are actually attributed to lug-centered spacers. Due to the non-hub-center design, there is a gap between the vehicle hub and the rim, which means that the rim is lug-centered rather than hub-centered. Without solid contact and lacking support from the hub, the lug bolts act as a shock absorber to the road. Some violent impact forces are enough to deform the bolt so that the rim is no longer concentric with the hub, leading to vibration.

Conclusion

The Mercedes-Benz G-Class is one of the top 10 best 4x4s and off-road cars of 2022 not only because of its excellent off-road performance but also because it offers the driver an unprecedented driving experience. BONOSS also believes in personalizing the vehicle with modifications to the chassis suspension, fitting wheel spacers, and so on, to give the driver a better driving experience.