For truck owners aiming to boost capability and style, wheel spacers are more than an aesthetic upgrade—they’re a performance enhancer. By safely pushing your wheels outward, spacers widen your truck’s track width, delivering tangible benefits for both on-road handling and off-road adventures. Here’s when spacers become a smart move:

- You need enhanced stability on challenging terrain like rock trails or sand dunes.

- You’re upsizing tires or installing aggressive off-road wheels.

- You want that muscular, planted stance stock setups often lack.

Key Benefits of Properly Sized Wheel Spacers

Choosing the right spacers improves both function and form:

Boosted Stability & Control: Widening the track distributes weight more effectively, significantly reducing body roll. This translates to better control on uneven surfaces, in crosswinds, or during evasive maneuvers.

Improved Off-Road Clearance: Spacers create crucial room for larger tires or suspension components, eliminating tire rub issues common with serious off-road builds.

Aggressive Styling: Achieve that sought-after, wide-tracked look. Proper spacers fill out the wheel wells, giving your truck a commanding, head-turning presence.

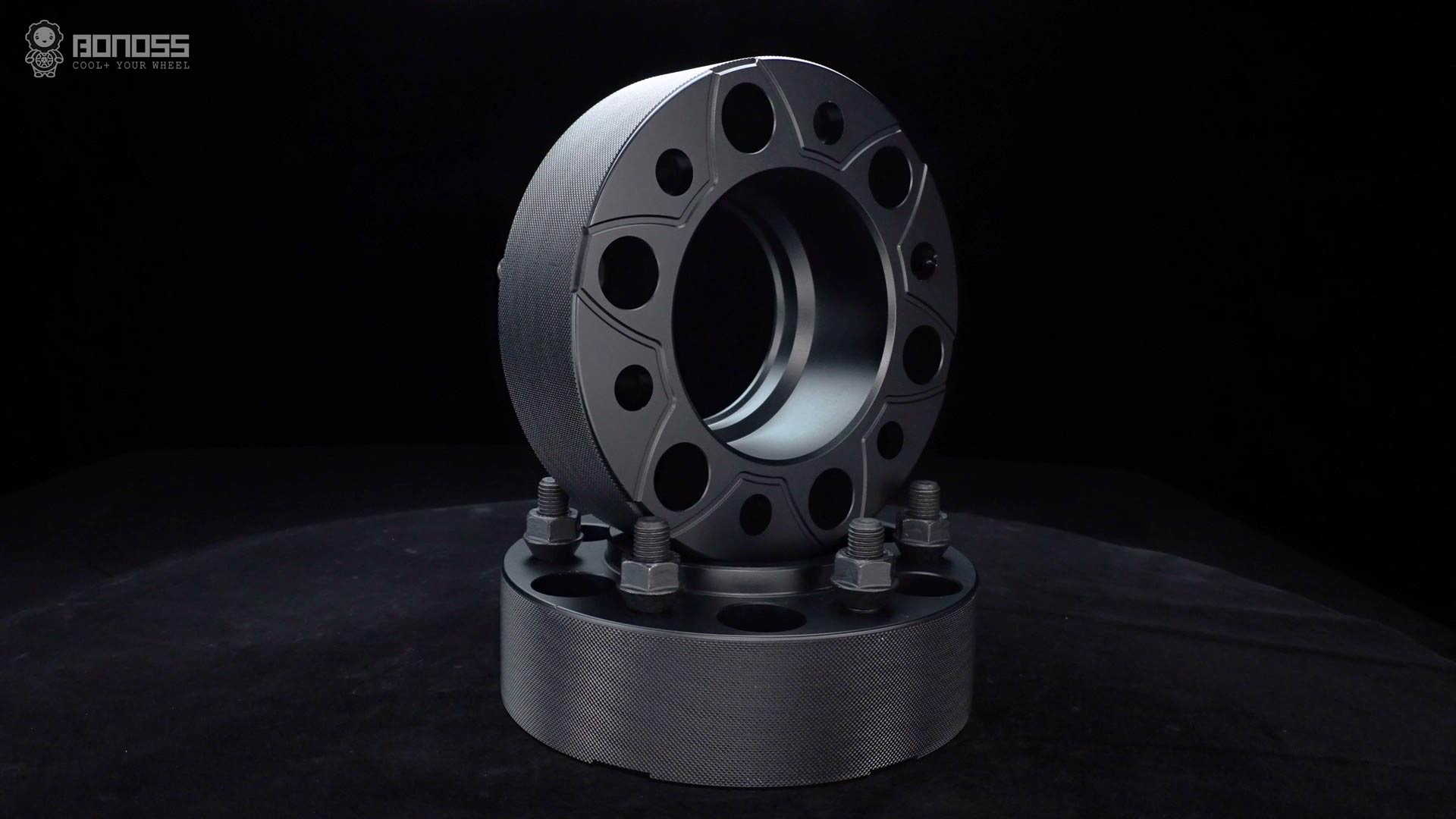

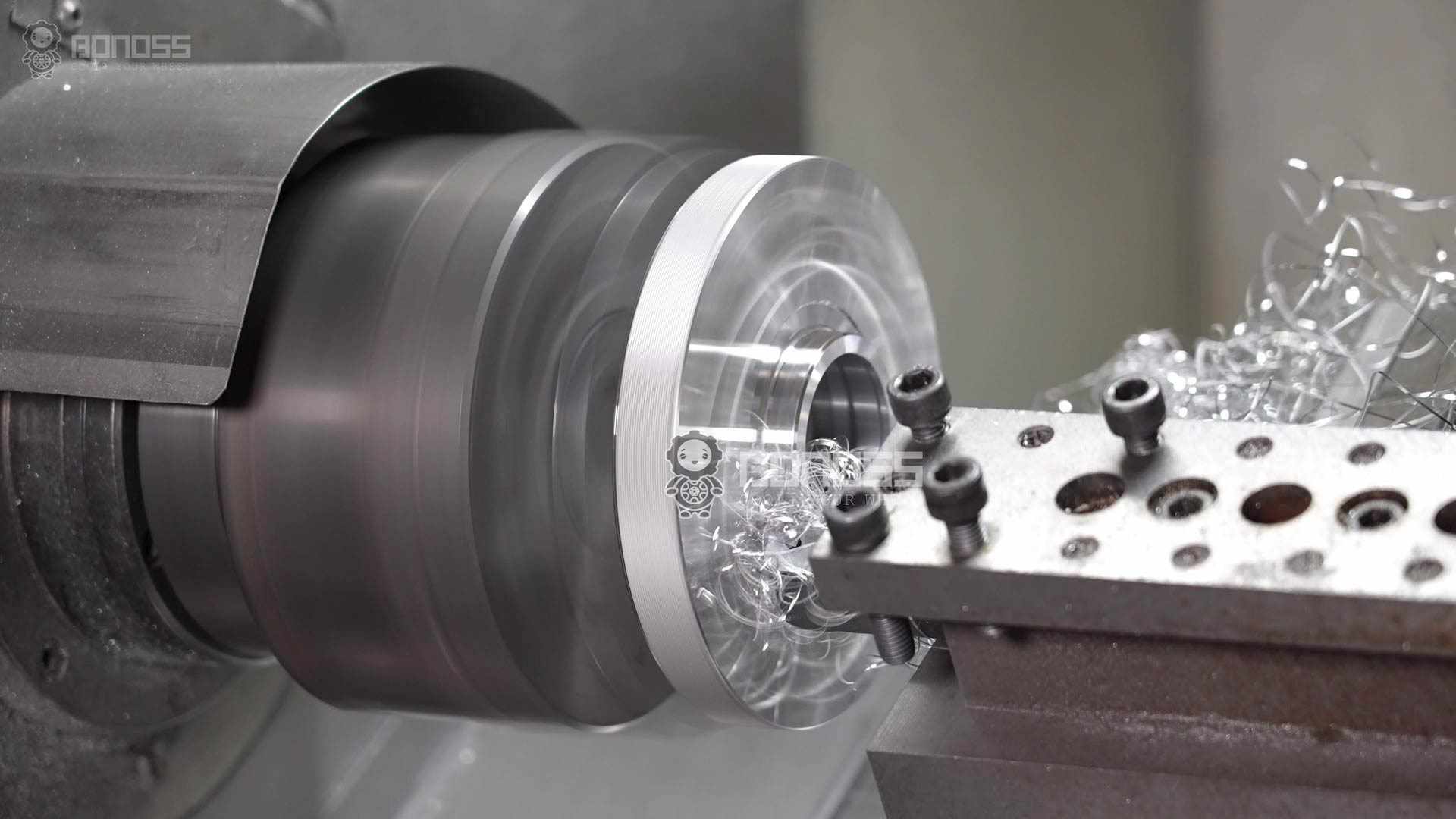

Advanced Functionality (Premium Brands): Leading brands like BONOSS integrate innovations like their Forged Active Cooling Spacers. Featuring patented heat-dissipation grooves machined into the spacer body, this design promotes constant airflow during rotation.

Investment: Cost & Quality Considerations

Installation: Professional installation is recommended. Most shops charge 100−150 USD per hour labor. Installation typically takes 20-60 minutes per axle depending on design.

Spacer Cost: A quality set of 4 spacers ranges from 160 to 700+ USD, influenced by thickness, material (forged aluminum is premium), brand reputation, and engineering. Investing in genuine, trusted brands ensures:

Rigorous safety testing and reliability.

Premium materials (e.g., T6-6061 forged aluminum).

Critical safety components: ISO 12.9 studs (min. 1220 MPa tensile strength) and ISO 10 nuts (min. 1100 MPa proof load).

Superior designs like Full-Cone Lug Seats (BONOSS) for maximum contact area and clamping force, virtually eliminating loosening risks.

Strong warranties and customer support.

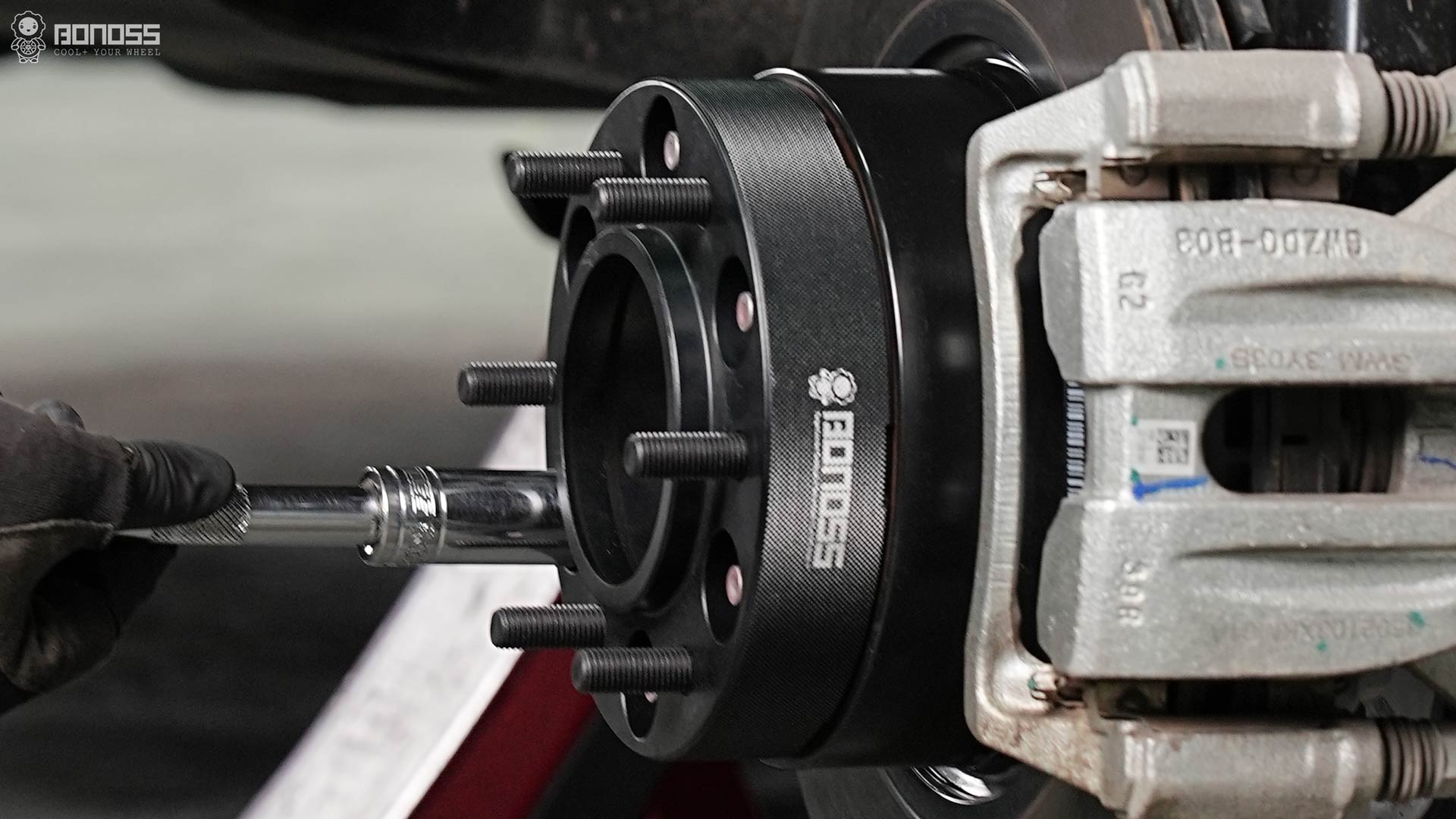

Installation: Straightforward but Precision Matters

Installing quality spacers is generally manageable for experienced DIYers, but precision is non-negotiable for safety and performance.

Prep Work: Double-check lug pattern compatibility (e.g., 6x135mm). Thoroughly clean hub and wheel mounting surfaces. Ensure spacer thickness aligns with tire/wheel/suspension mods.

Mounting: Use a calibrated torque wrench! Tighten lug nuts/studs to the spacer manufacturer’s exact specifications. This prevents shifting or loosening.

Post-Installation: Re-torque lug nuts after the first 50-100 miles. Periodically inspect spacers, especially after hard off-road use. Quality spacers, correctly installed, will not prematurely wear bearings or affect alignment.

The Bottom Line: Wheel spacers are a proven upgrade for truck enthusiasts seeking better performance, clearance, and style. The key lies in selecting high-quality, safety-engineered spacers from reputable brands and ensuring precision installation and maintenance. Do it right, and you’ll unlock significant benefits without compromising safety or reliability.