The core function of MG ZS wheel spacers is to change the offset (ET value) of the wheel hub. Installing MG ZS wheel spacers brings about several changes to the vehicle. Firstly, the ET value of the original wheel hub decreases or even reaches a negative value, depending on the thickness of the MG ZS wheel spacers you purchase (the ET value of the factory vehicle is generally between 35-50 millimeters). Secondly, the distance between the coaxial wheels increases, bringing the position of the wheel hub closer to the body line, achieving an aesthetic purpose.

Thirdly, the modification space of the wheel hub becomes larger, which is why MG ZS wheel spacers are considered auxiliary accessories for installing larger brake calipers. One of the negative impacts is that choosing MG ZS wheel spacers with excessive thickness increases the probability of friction with the steering wheel. This requires communication with BONOSS customer service personnel to obtain the most suitable product.

Based on the basic principles of mechanics, when installing MG ZS wheel spacers to increase the wheel track, it helps to evenly distribute the weight of the vehicle, thereby assisting in maintaining stability during driving within limits allowed by the vehicle chassis. Of course, considering the vehicle’s balance, you must choose suitable MG ZS wheel spacers to minimize the impact on the chassis.

What Are MG ZS Wheel Spacers Made of?

The most commonly used materials for MG ZS wheel spacers are 6061-T6 and 7075-T6 forged aluminum alloys. However, you may also come across iron-made MG ZS wheel spacers, but their weight is a noticeable disadvantage. Both grades of forged aluminum alloys are safe, and BONOSS engraves the material grade on each wheel spacer to ensure that customers clearly understand the product’s performance.

First, we must understand the difference between forged and cast metal materials for MG ZS wheel spacers. Cast metal materials are more suitable for parts that are difficult to machine, but their mechanical properties are inferior to forged parts. The drawbacks of castings include coarse grain structure, numerous defects, unstable casting quality, and the presence of air during the part-forming process, leading to the formation of gas holes.

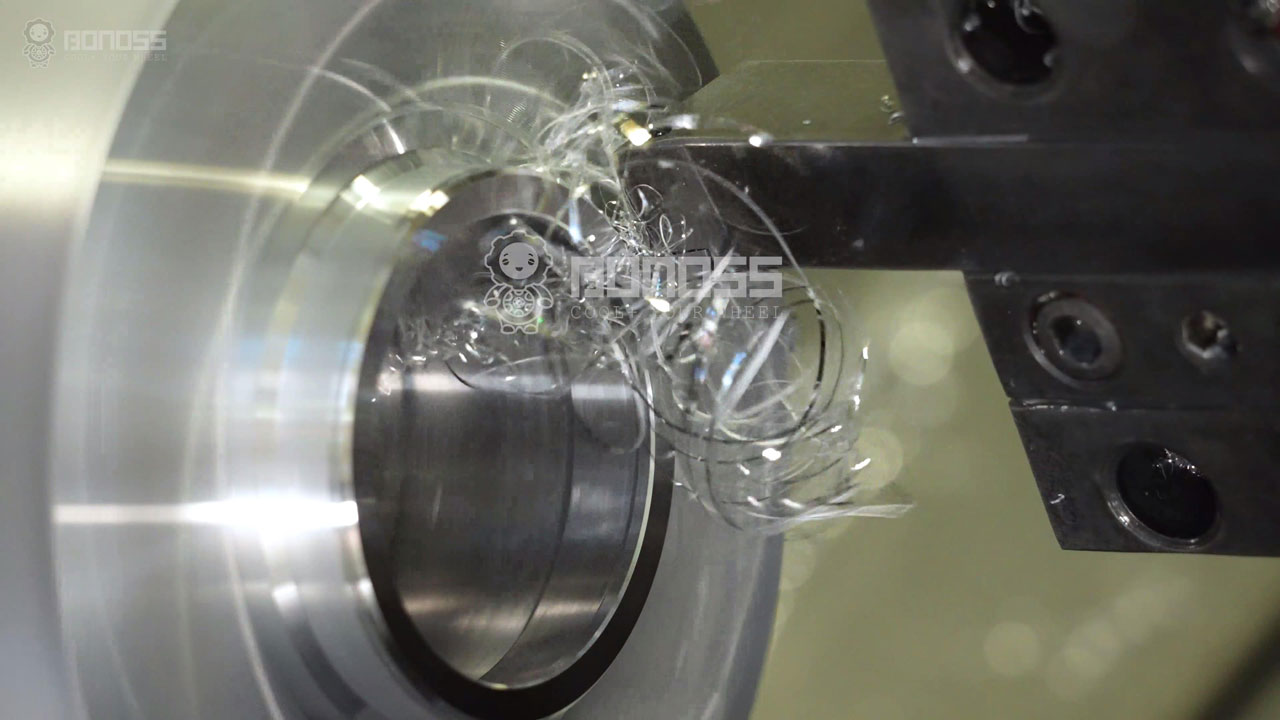

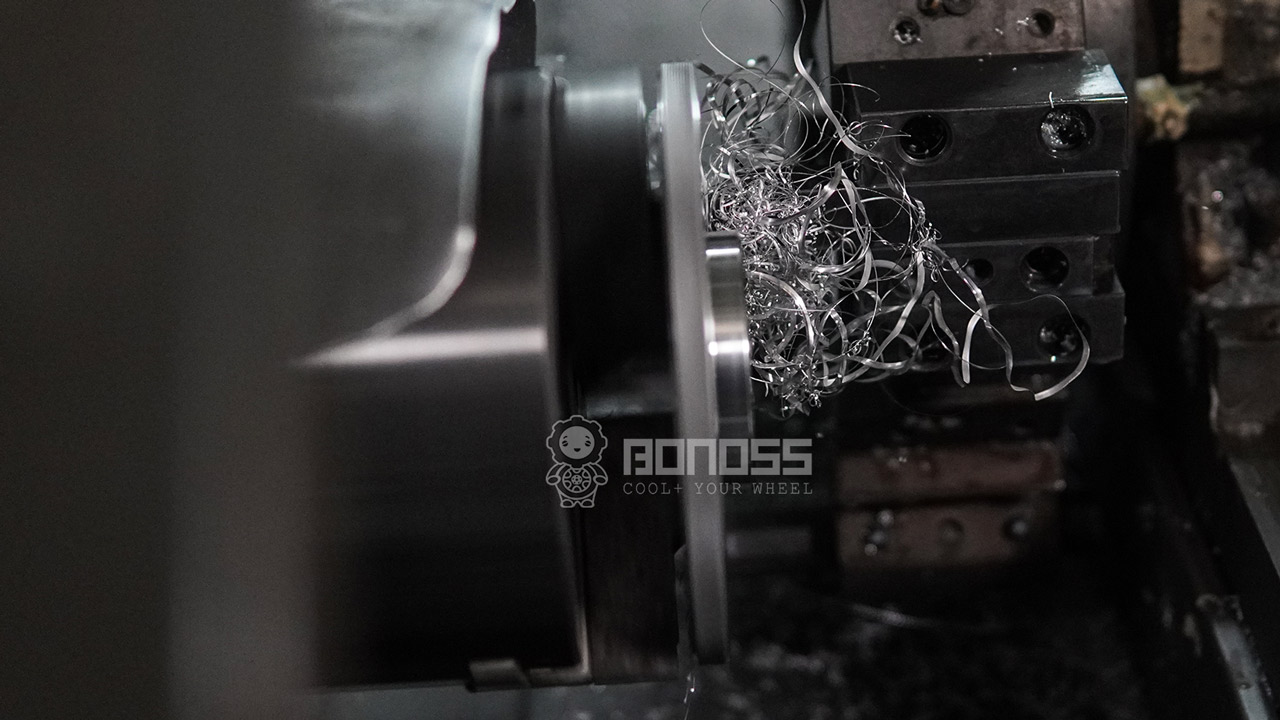

MG ZS wheel spacers made of forged aluminum alloy undergo high-pressure external forces. Forging machines apply pressure to the aluminum alloy billet, causing it to undergo plastic deformation to obtain certain mechanical properties and specific shapes. MG ZS wheel spacers are manufactured from the forged aluminum billet after the forging process. The wheel spacers of the desired thickness are cut from the billet, followed by precise cutting using high-precision CNC cutters.

Forged MG ZS wheel spacers eliminate defects such as porosity that may occur during the metal casting process. The optimized microstructure is denser, eliminating gas holes and other defects. Furthermore, since the complete metal flow lines are preserved during the forging process, forged parts generally have better mechanical properties than castings of the same material. They are suitable for critical components in machinery that experience high loads and harsh working conditions.

What Are BONOSS MG ZS Wheel Spacers Made of?

BONOSS provides a detailed comparison of material performance on the purchasing page of MG ZS wheel spacers. 6061-T6 and 7075-T6 are safe and reliable materials, so there is no need to be overly concerned. However, there is a difference in price between the two materials, mainly due to the superior material performance exhibited by 7075-T6. Some car owners also recommend using MG ZS wheel spacers made of 7075-T6 material, which provides added peace of mind.

- Forged 6061-T6 MG ZS wheel spacers have an ultimate tensile strength of 42,000-45,000 psi and yield strength of 35,000-40,000 psi. These two critical data determine the performance limits of MG ZS wheel spacers.

Ultimate tensile strength refers to the material’s ability to resist failure under external forces, and strength testing often requires the destruction of the material to obtain the ultimate value. Yield strength refers to the limit at which a metal material exhibits plastic deformation, i.e., the stress at which the material resists slight plastic deformation.

- The 7075-T6 forged aluminum alloy MG ZS wheel spacers provided by BONOSS perform exceptionally well in both values. Its ultimate tensile strength can reach 74,000-78,000 psi, and its yield strength is 63,000-69,000 psi, approximately 40% higher than the standard material 6061-T6.

The forged aluminum alloy MG ZS wheel spacers BONOSS produces are treated with a hard anodized anti-rust coating. Hard anodizing is a thick-film anodizing process, a special surface treatment for aluminum and aluminum alloys. With this process, the maximum thickness of the anodized film can reach around 250 micrometers. A microhardness of 1500 kg/mm² can be achieved on pure aluminum, while a microhardness of 400-600 kg/mm² can be obtained on aluminum alloys.

The main purpose of BONOSS’s hard anodizing treatment on MG ZS wheel spacers is to enhance various properties of the aluminum alloy, including corrosion resistance, wear resistance, weather resistance, insulation, and adsorption, among others.

Are MG ZS Wheel Spacers Accessories Matter?

When considering the reliability and safety of MG ZS wheel spacers, it is essential to understand the material of the spacer itself and the material of the wheel bolts, as they are responsible for securing the wheel hub and the wheel spacers. The chassis structure of the MG ZS utilizes wheel bolts for fixation, which means that both slip-on and bolt-on types of products are suitable for this vehicle.

When choosing slip-on MG ZS wheel spacers, you must pair them with longer wheel bolts to accommodate the additional spacing. BONOSS provides 12.9-grade extended wheel bolts compatible with the wheel spacers, but they are not included in the purchase combination.

The 12.9-grade extended wheel bolts are made of SCM440 forged steel alloy. They are also rated based on their tensile strength and yield strength. Most factory wheel bolts only provide 10.9-grade products, while 12.9-grade high-strength wheel bolts were initially designed for heavy-duty trucks. Pairing the MG ZS wheel spacers with 12.9-grade wheel bolts ensures better safety. BONOSS’s manufacturing standards aim to provide customers with high-performance products rather than ordinary wheel bolts.

- Wheel bolts in the structure need to withstand the clamping force applied by a torque wrench, shear stress, and stress generated from temperature changes. The 12.9-grade steel alloy wheel bolts can withstand a tensile strength of 1220 MPa, while the original 10.9-grade wheel bolts only support strength of 1040 MPa. The proof load of 12.9-grade wheel bolts can reach 121,000 N, while 10.9-grade wheel bolts have only 104,000 N.

- Regarding the Limited Life Range, the 12.9-grade product can endure 2,000,000 stress cycles, while the 10.9-grade product only lasts half as long. Whether used with MG ZS wheel spacers or as a replacement for the original wheel bolts, the 12.9-grade wheel bolts are the ideal choice.

Why Are MG ZS Wheel Spacers a Subject of Controversy yet still Adopted by Many People?

We can provide an example shared by a car owner.

The owner saved up to purchase genuine two-piece forged wheels from Work. Later, they installed wider fenders on their vehicle, adding two centimeters to the width. At this point, changing to a new set of wheels becomes quite challenging due to the offset (ET) requirements. Therefore, using MG ZS wheel spacers became a cost-effective choice.

Those who hesitate about purchasing MG ZS wheel spacers, can rest assured. According to the customer’s experience, the owner has used the wheel spacers for over two years without encountering any issues. Many other customers have been using them for even longer periods.

BONOSS has been designing and manufacturing wheel spacers since 2007. Our professional production experience and excellent product quality give us the confidence to provide an extended 10-year warranty for MG ZS wheel spacers, which far exceeds the warranty periods offered by most brands. BONOSS promises to provide warranty service for any quality issues with our products within 10 years. Please refer to the warranty for more details.

(Some photos come from our clients, if there is any infringement, contact us immediately to delete them.)