Nothing strikes dread into a 4Runner owner’s heart faster than the telltale clunk of a loose wheel lug nut. Allowed to progress, Toyota 4Runner lug nut loosening can lead to catastrophic wheel detachment and more damage than you can imagine. But what causes this critical component to fail in the first place?

Why Do Toyota 4Runner Lug Nuts Come Loose?

Over-Torquing

It may seem counterintuitive, but over-tightening lug nuts is a prime cause of loosening. Excessive torque stresses the fastener past its limits, stretching threads and distorting the nut’s shape. This leads to reduced clamping force, vibration, and eventually total loosening. Always torque wheels to spec with a properly calibrated wrench.

Under-Torquing

On the flip side, failing to achieve adequate torque during installation allows the wheel to work free under normal loads. Proper lug nut torque ensures clamping force remains within design limits to combat vibration and resist loosening. Never estimate – always torque.

Poor Maintenance

The repetitive torque inconsistencies of oil change and tire rotation pit crews take a cumulative toll on lug nut integrity over time. Technicians rushing to complete jobs often under or over-torque. Request your servicer use a calibrated wrench at factory torque specs.

Inferior Materials

Many factory supplied and cheap aftermarket lug nuts use substandard materials prone to stripping and stretching at high torque and loads. Upgrading to performance lug nuts made from stronger alloys provides more consistent clamping force.

Damaged Studs/Holes

Distorted, bent or corroded wheel studs prevent the lug nut from securing properly against the wheel, while out-of-round lug holes allow movement under torque. Inspect and replace damaged studs/holes to restore wheel integrity.

Dissimilar Metals

Pairing steel wheels with aluminum lug nuts leads to oxidization as the metals corrode. The resulting buildup compromises the connection, allowing the nut to loosen over time. When possible, match lug nut material to the wheel.

Loose Hubs

If the actual hub assembly has excessive play, no amount of lug nut torque will secure the wobbling wheel. Worn bearings, damaged fasteners and general looseness requires hub service to address the root issue.

Poor Design

Some factory lug nut configurations inherently loosen easier due to insufficient thread engagement, lightweight materials, poor accessibility and other design factors. Certain OEM lug nuts are simply destined to fail.

Off-Roading Damage

Punishing off-road conditions bend studs, distort holes, and damage fastener threads. The resulting loss of wheel integrity leads to rapid loosening. Carefully inspect mounting hardware after rocky trails and replace damaged parts.

How Can I Fix Persistent Loosening?

Regular lug nut re-torque and immediate attention to any loosening can help address the issue. But often, the weak link is inadequate lug nuts themselves. Upgrading to aftermarket, heavy-duty lug nuts engineered for robust durability restores confidence. Here’s what to look for:

Chrome alloy or stainless steel construction

Computer-controlled precision machining

Flange style for easier access

12-point double hex shape to prevent stripping

Matched thread pitch/length for 4Runner wheels

Exceeds OEM specs for longevity and security

Why BONOSS Toyota 4Runner Lug Nuts Won’t Loosen?

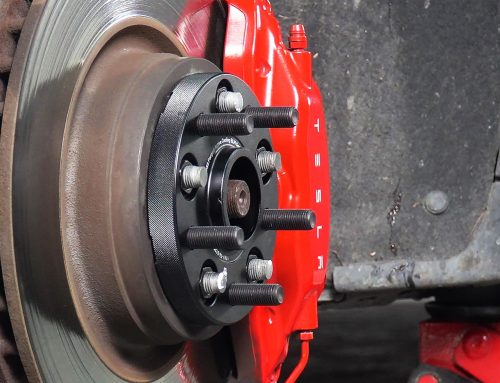

For Toyota 4Runner SUV owners, a persistent concern can be keeping wheel lug nuts properly tightened. Gravel roads, off-road trails, and even potholed city streets can cause lug nuts to gradually loosen over time, presenting a major safety issue if left unchecked. Upgrading to aftermarket lug nuts engineered to resist loosening provides added peace of mind. Here’s a look at how BONOSS Toyota 4Runner lug nuts are designed to stay tight.

Controlled Torque Specs: Proper torque application is also a key factor BONOSS emphasizes. Their lug nuts are first tested and calibrated to achieve optimal clamping force at the vehicle’s factory torque setting. Hundreds of installs and removals ensure the nuts stay within proper torque range to prevent under or over-tightening. The controlled torque range then allows the locking mechanisms to fully engage. This complements the precision manufacturing.

Robust Materials: In addition to steel construction, BONOSS adds protective surface plating. Choices like black coatings further boost corrosion protection, even in harsh winter road salt or coastal humidity conditions. This prevents any rust or seizing that could loosen the lug over time. Stainless steel is also available for marine and other highly corrosive environments.

No Plastic Caps or Covers: Many factory lug nuts rely on cheap external plastic caps or covers to try resisting loosening. But these defeat the purpose when they eventually fail, break, or fall off allowing the nut to then unwind. BONOSS instead uses high-integrity metals and internal geometry for true longevity against loosening without any fragile external parts.

Affiliate Content: