The 6×139 wheel spacers push the wheels outward to create a more aggressive and muscular look. It also improves stability. This is especially beneficial for off-roading, where a wider tack allows the tires to better grip uneven terrain. Another benefit of spacers is clearing the large brake components. This allows you to run those cool custom rims without issues.

As long as you torque each lug nut correctly, the 6×139 wheel spacers won’t break or fail easily. Always purchase from a reputable brand. Genuine brand wheel spacers are trustable because of their quality and performance. A set of strong forged aluminum wheel spacers can handle more forces without breaking.

Top 5 Pro Tips for Installing 6×139 Wheel Spacers Safely

Every time you perform routine maintenance, remember to check the condition of the lug nut tightness. Here are some expert tips of correctly torquing 6×139 wheel spacers:

Clean the Thread:

When torquing the lug nuts, make sure that the stud and nut threads are clean and dry with no oil, or grease. Don’t apply lubrication to the wheel’s hardware.

Use a Torque Wrench:

It is recommended to use a good torque wrench to tighten the wheel spacers to proper torque specs. Set the torque wrench to the manufacturer’s recommended value. Then simply turn the wrench handle until it reaches the torque mark.

Correct Torque Specs:

The REFERENCE torque spec on the 6×139 wheel spacer is 113 Nm for M12 lug nuts or 140 Nm for M14 lug nuts. For some wheels or applications, you may need more or less tightening torque. So, it’s best to consult a tire specialist to ensure the exact torque spec before operating

Proper Sequence:

Start threading the hardware by hand, then use the torque wrench to tighten spacer wheel nuts in a crisscross sequence. When the lug nuts are properly torqued down, you will feel a click around the head of the wrench. Don’t trust an impact gun can settle everything down.

Re-torque the 6×139 wheel Spacers:

it is crucial to re-torque your new wheel spacers after the first 50 to 100 driving miles. Then, just re-torque them every routine tire maintenance. By torquing each lug nut to the proper torque specification, your new 6×139 wheel spacers will safely function.

What Are the 6×139 Wheel Spacers?

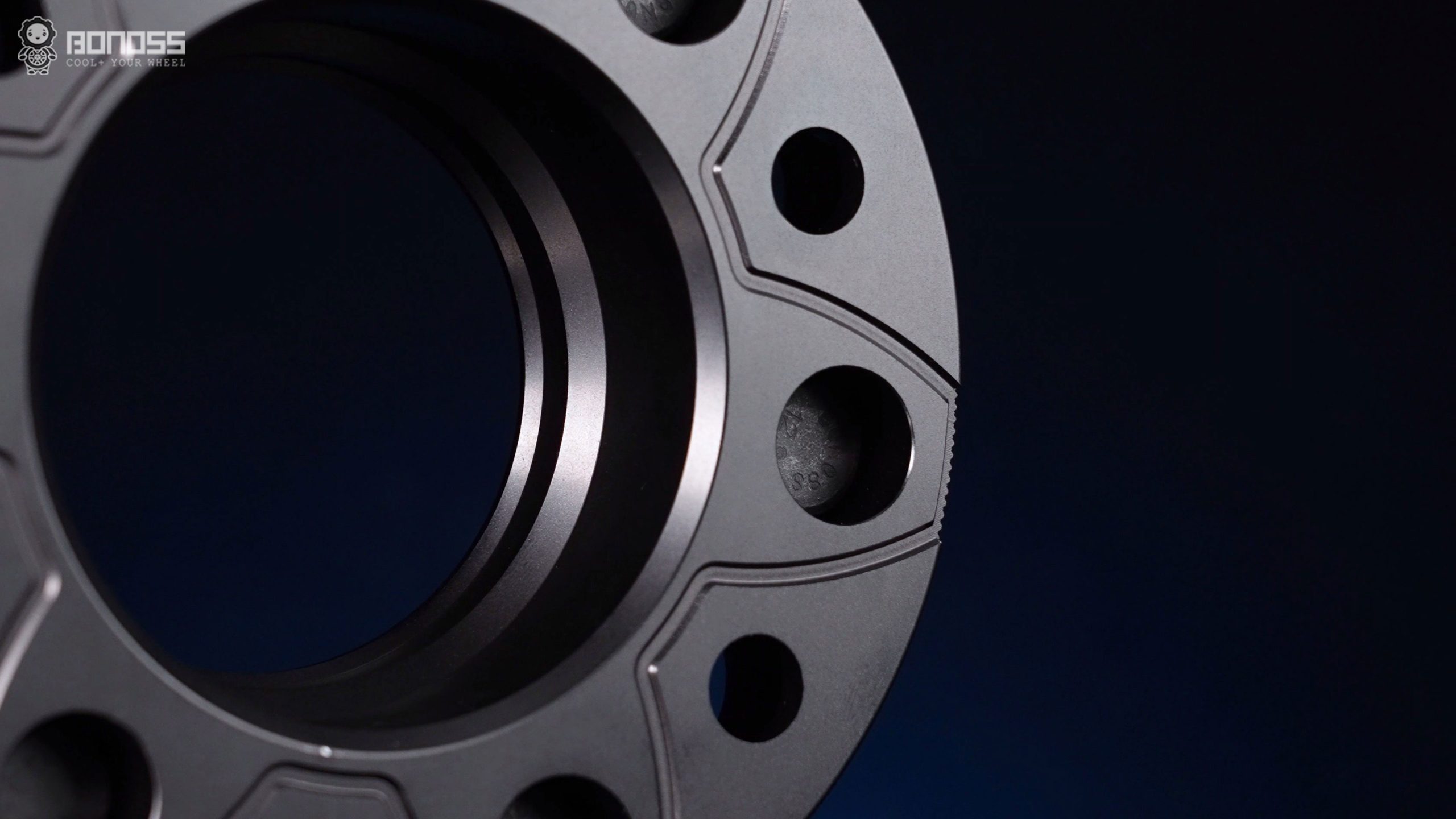

High-end wheel spacers are produced with top-quality materials to provide optimum performance to the vehicle. For example, BONOSS forged active cooling 6×139 wheel spacers are made of advanced machinery and undergo a series of safety tests before leaving the factory. BONOSS offers several key advantages that make their spacers a top choice.

1. Active Cooling for Safe Upgrades

BONOSS forged active cooling 6×139 wheel spacers are helpful in improving brake cooling efficiency. The heat dissipation grooves send the external cold air to flow continuously inside the wheel spacer when it rotates. The air takes away the heat to actively dissipate heat for the braking system. This boosts the cooling efficiency, reducing brake thermal decay, and improving road safety.

2. Stronger Fasteners for Improved Safety

BONOSS forged active cooling 6×139 wheel spacers come with ISO grade 12.9 wheel studs. These wheel studs are approved by SGS and TÜV:

- Tensile strength≥ 1,220 MPa;

- Limited life range test≥ 2,000,000 stress cycles without damage;

- Ultimate tensile load≥ 152,000 N;

- Hardness (HV)≥ 395;

- Neutral Salt Spray≥ 500H.

Arguably, a stronger retention power on the wheel is necessary to properly secure the spacer and wheel in place.

3. SGS TUV Tested for Guaranteed Safety

Made of advanced machinery and undergone a series of safety tests, BONOSS forged active cooling 6×139 wheel spacers are approved by over 75 SGS TÜV test reports. These SGS TÜV-certified wheel spacers are completely safe and legal to use.

Final Verdict: Elevate Your Car with BONOSS

With these outstanding advantages, it’s clear that BONOSS forged active cooling 6×139 wheel spacers are the best option. Whether you’re upgrading the aesthetics or improving the handling, choosing BONOSS ensures that you’re getting a product that meets the highest standards of performance and quality. Your car deserves the best.

(Hi, I’m Kevin Brian, an experienced mechanical engineer. All articles, images, and videos are human-produced to ensure the best user experience. They are not generated by Artificial Intelligence (AI) Models or tools.)