Vehicle-specific 5×114 3 wheel spacers are machined to your vehicle specification, which ensures perfect fitment. When the spacers are firmly installed on the hub assembly, there will be no gap. A perfect fitment brings a snug wheel connection. The wheels can affect the stability and handling of the vehicle. Thus, it is important to use the correct OEM wheel spacers.

The universal aftermarket 5×114 3 wheel spacers, on the other hand, are designed to fit different vehicles. They are made with bigger hub diameters so that they don’t need to care about the actual vehicle hub design. It is always recommended to use specific 5×114 3 wheel spacers. In this post, we will explore the best wheel spacers and top brands.

5×114 3 Wheel Spacers: Hub-centric vs. Lug-centric

Whether a 5×114 3 wheel spacer is hub-centric or lug-centric depends on how the spacer fits onto the vehicle.

Hub-centric 5×114 3 wheel spacers are centered on the vehicle hub by machined center rings. The center rings of the spacers are sized to fit perfectly onto the vehicle hub and wheel mounting flange. Therefore, these wheel spacers are centered by the axle hub and the lugs can hold the wheels stably and firmly. This is a hub-centric connection, which keeps your vehicle from experiencing unnecessary vibration.

Lug-centric wheel spacers are centered on the vehicle hub by the wheel lugs only. Typically, they come with big center holes. When remounting the wheel, there will most likely be a gap between the vehicle hub and the wheel hub flange. Without a firm contact, some fierce impacts are strong enough to unbalance the wheel and deform the wheel studs, leading to vibration.

Why BONOSS 5×114 3 Wheel Spacers the Best Choice?

When selecting the best 5×114 3 wheel spacers, BONOSS stands out in terms of safety and performance. With the advanced technology and unmatched quality, BONOSS offers several key advantages that make their spacers a top choice.

1. Effective Active Cooling Benefits

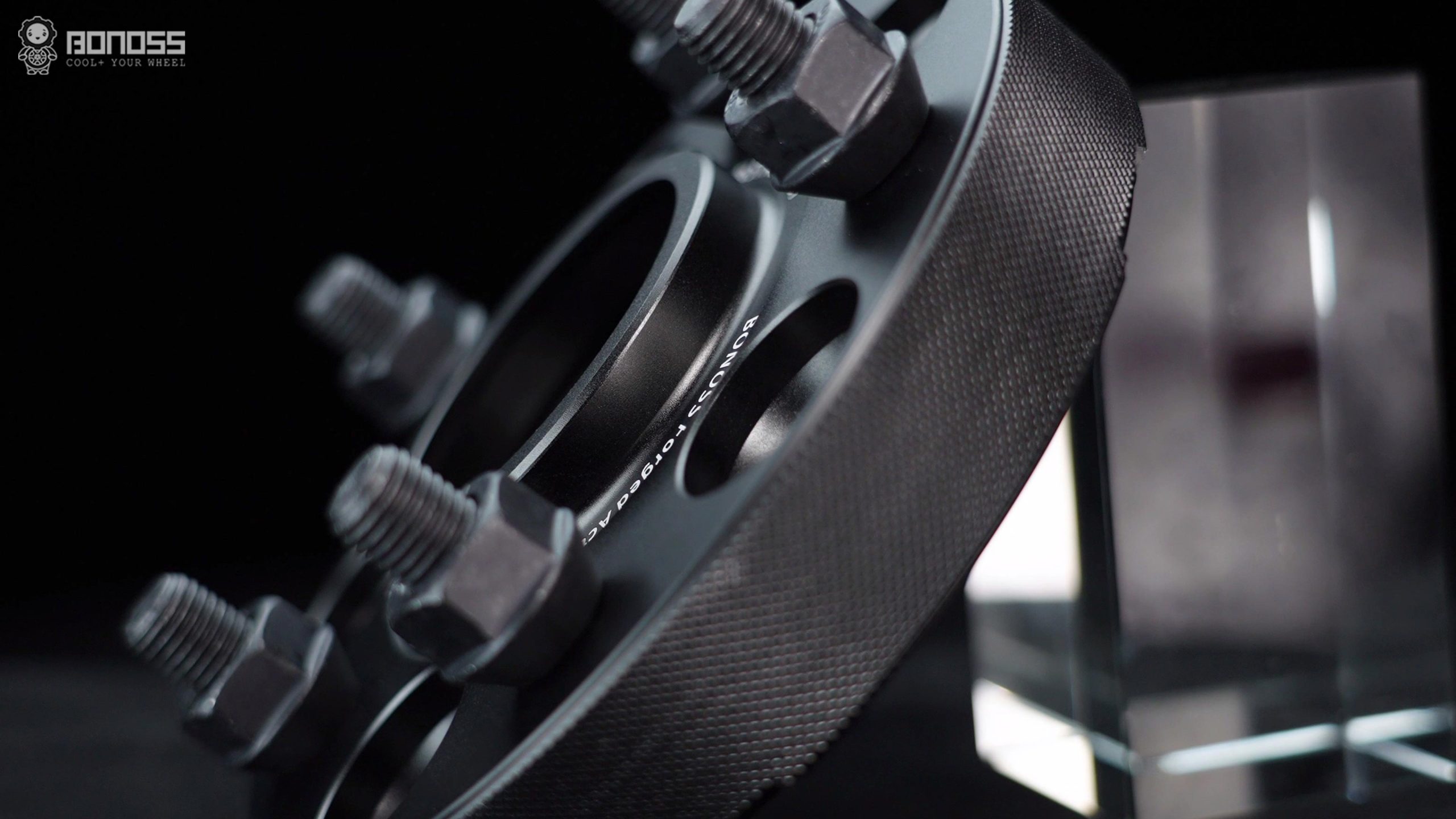

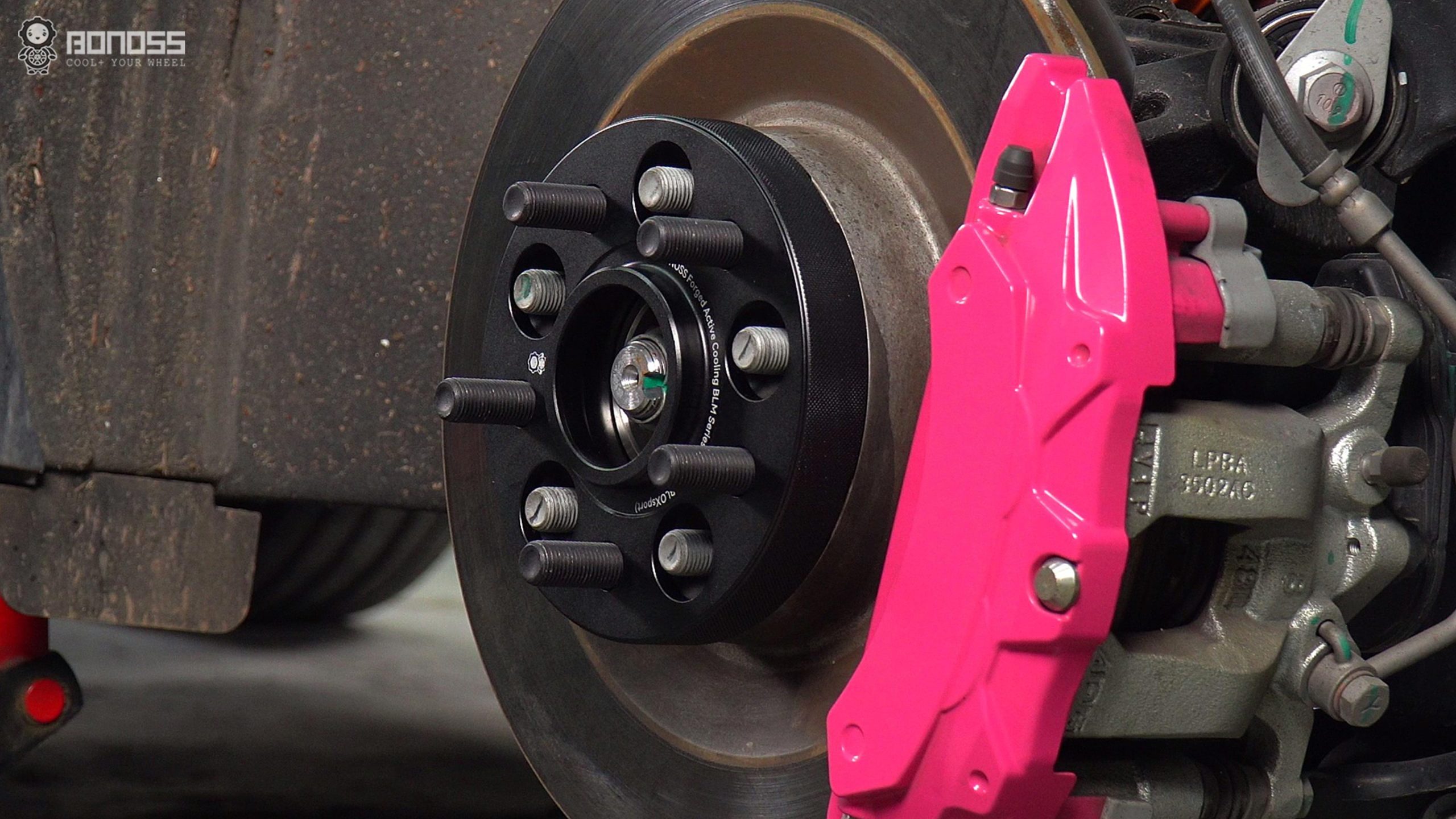

Aside from the basic functions, BONOSS forged active cooling 5×114 3 wheel spacers provide more additional advantages. For example, the active cooling technique. Distributed in petal shape, the cooling grooves allow the external cold air to flow continuously inside the wheel spacer when it rotates.

The flowing air takes away the heat, so it boosts the heat dissipation efficiency of the rotors, reducing brake thermal decay, and improving road safety. In addition, the side knurling design eliminates internal stress and enlarges the cooling area which is good for the active cooling effect.

2. Hub-centric with Zero Vibration

In order to further optimize the hub-centric connection, BONOSS forged active cooling 5×114 3 wheel spacers are designed with better multi-stage hub-centric lips. The hub-centric metal ring is machined to be multi-layers, and the bevels fit the corresponding hub flange, which eliminates any possible wheel vibrations.

3. Aerospace-grade Aluminum

Brands that focus on quality and performance are very strict in raw materials and manufacturing processes. For example, BONOSS forged active cooling 5×114 3 wheel spacers are made of high-strength 6061-T6 and 7075-T6 aluminum alloy materials. The ultimate tensile strength specs of these two aluminum alloys are:

- Forged 6061-T6 spacers: 42000-45000 psi (300-310 MPa);

- Forged 7075-T6 spacers: 74000-78000 psi (510-572 MPa).

4. Full-cone Seat with Zero Loosen

Full-cone seat design provides a larger contact area, more force acreage, and better fitting. This allows the studs and nuts to apply enough clamping force to lock the BONOSS forged active cooling 5×114 3 wheel spacers. In that case, the hub-spacer-wheel connection can be fastened firmly, meaning no vibration.

Final Summary: Make Your Car Better with BONOSS

From innovative active cooling benefits to certified materials and precise manufacturing, BONOSS forged active cooling 5×114 3 wheel spacers are engineered to enhance your driving experience with safety, strength, and reliability. Discover the difference with BONOSS—built for drivers who demand excellence.

(Hi, I’m Kevin Brian, an experienced mechanical engineer. All articles, images, and videos are human-produced to ensure the best user experience. They are not generated by Artificial Intelligence (AI) Models or tools.)