As tire experts claim, it is optional to use anti-seize on Toyota LC300 wheel spacers. Anti-seize products are generally applied to bolts, fasteners, and other clamped interfaces to prevent galling, seizing, and corrosion, as well as lubricating to ease disassembly. With the development of modern manufacturing technology, many famous brand LC300 wheel spacers are well-treat in corrosion resistance. This means they won’t easily corrode or get stuck on your vehicle hub. As long as you use quality wheel lugs and properly torque them, they will never come loose.

But using anti-seize on LC300 wheel spacers is completely harmless. If you don’t intend on removing the LC300 wheel spacers after installation, then use Red Loctite. Red is permanent. But if you would like to use LC300 wheel spacers for a certain period, Blue will be fine. When applying a Loctite threadlocker, make sure the nuts and studs are clean and free from oil or dirt. Both surfaces must be clean to develop full bonding strength. Use a good torque wrench and tighten LC300 wheel spacers to the correct specs, you are worry-free of wheel spacer failure.

Can LC300 Wheel Spacers Rust?

Quality brand LC300 wheel spacers won’t rust even after a long time. Nowadays, most wheel spacers are made of aluminum alloys. When aluminum is exposed to water it creates a film of aluminum oxide over the metal that protects the metal beneath it from corrosion. Due to the super forging process, BONOSS forged active cooling aluminum alloy LC300 wheel spacers have better corrosion resistance. The increased performance ensures safety on the road even when you accidentally come across an obstacle.

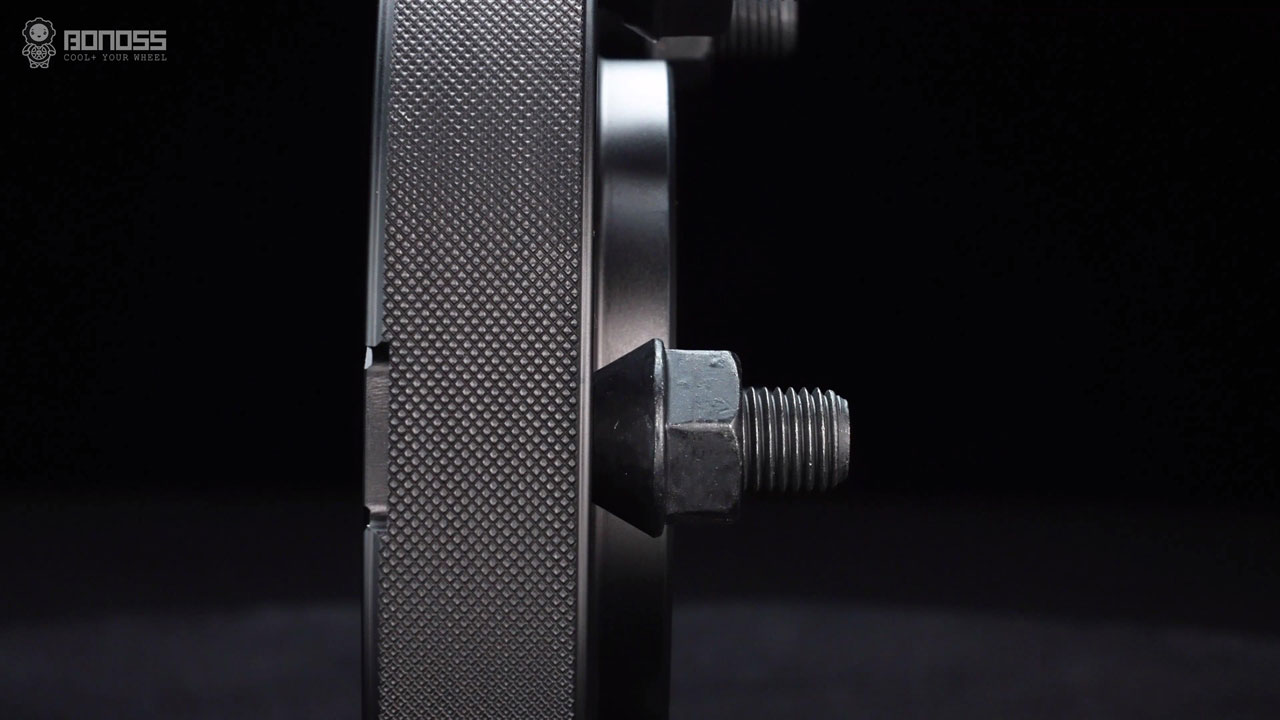

Additionally, a good rustproof coating is effective to protect LC300 wheel spacers from corrosion-related failure. BONOSS offers a black hard coat anodizing service. Anodizing provides the surface with better abrasion resistance, flame resistance, and smoother and harder finish protection than regular paint or metal plating. Particularly, BONOSS wheel studs and lug nuts give salt spray resistances exceeding 500 hours, which improves the corrosion resistance ability greatly. In other words, when installing genuine BONOSS forged active cooling LC300 wheel spacers, you don’t have to use Loctite.

Is It Hard to Remove LC300 Wheel Spacers?

Removing LC300 wheel spacers isn’t hard. However, if you use Loctite on the wheel spacers, things may be a little troublesome when you intend to remove the LC300 wheel spacers for routine maintenance. That is because the threadlocker will glue the studs and nuts together. It makes the removal process hard. But like any other adhesive, using a heat gun to melt it will be useful.

To make the removal process easier, BONOSS forged active cooling LC300 wheel spacers come with disassembly grooves. The disassembly grooves refer to the small notches which are distributed on the corner of wheel spacers. Normally, a notch leaves a limited clearance between the brake rotor and the spacer. When removing the BONOSS forged active cooling LC300 wheel spacers, get a flat-head screwdriver and place it on one notch. Pound a hammer on the screwdriver at a 45-degree angle. It should come off pretty easily.