If you’re looking for wheel spacers, there are several things that you should consider. As wheel spacers are manufactured in a variety of methods and alloys, they have distinct advantages and disadvantages over one another. The most popular manufacturing processes are “forged” and “casting”. Each type is manufactured in a different manner and associated with different mechanical performance.

As manufacturing technology improves, modern car wheel spacers are getting more durable and tough. In short, forged wheel spacers are generally stronger than casting ones. If you have a performance-oriented vehicle then you will quickly want to move beyond the cheap casting options and get some forged wheel spacers. As we continue our discussion of spacers, we’ll take a peek at the difference between forged spacers and casting spacers.

Are Forged Wheel Spacers or Casting Spacers Better?

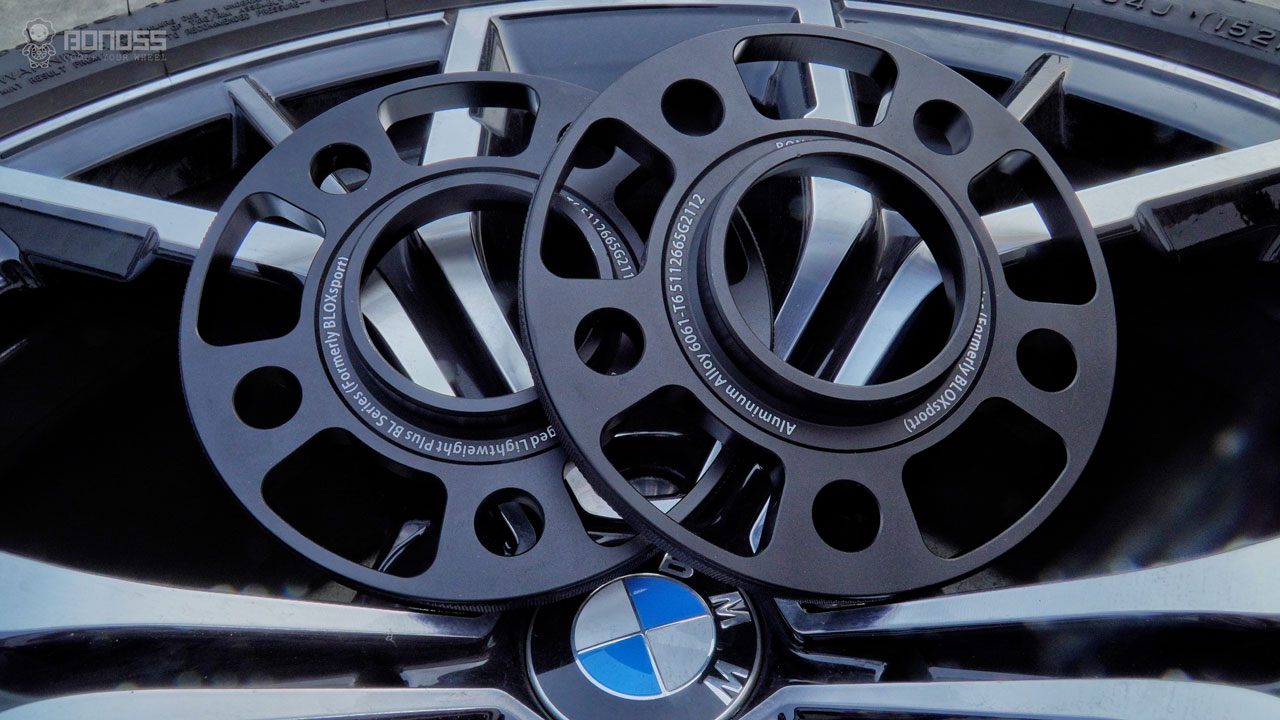

Forged wheel spacers are the pinnacle in aftermarket wheel spacers. They undergo continuous tons of pressure to form. This eliminates any porosity, shrinkage, and other micro-processes presented in the raw material. The resulting wheel spacers have a high degree of uniformity in the grain structure which allows the spacers to have a very high weight-to-strength ratio. As a result, forged wheel spacers can be much more durable with much less material. That is why forged spacers are far stronger as well as lighter than casting alternatives.

The only thing casting wheel spacers can beat forged ones is the price. Certainly, casting spacers are usually much cheaper than forged spacers. Because casting is usually quicker and easier than forging. Manufacturers mass-produce those spacers with cheap off-cut aluminum. The cost is less so the price is lower. However, you should be aware that cheap products often mean low-quality products. Because of cavities, porosity, and shrinkage, casting wheel spacers lack the tensile, torsional, or compressive strength to stay within the safety factor of their properly manufactured equivalents. The saved several dollars don’t worth it.

Forged 6061-T6 or 7075-T6 Wheel Spacers

In short words, forged 7075-T6 aluminum wheel spacers are significantly stronger than 6061-T6 alternatives. But they are also more expensive. Both these two forged aluminum wheel spacers are of good strength, toughness, hardness, and corrosion resistance. If you get forged 6061-T6 wheel spacers installed, the cost will be inexpensive compared to the 7075-T6 replacement. For those looking for cheaper but more durable options, forged 6061-T6 wheel spacers are the way to go.

7075-T6 aluminum alloy is one of the strongest types of aluminum available. Forged 7075-T6 aluminum wheel spacers feature a tensile strength that is nearly double that of 6061-T6 aluminum spacers. The yield strength of 7075-T6 types is estimated to be 1.5 times that of 6061-T6. Therefore, they withstand more impact force than 6061-T6. For racing, drift, and hard-driving, forged 7075-T6 spacers are the best option. You may spend more while you will experience more enjoyable as well.