If the wheel bolts are too long, they can’t properly fasten the wheels. Getting the wheel fastener length right is critical with regard to safe wheel installation. Sadly, people often overlook them, after all, they are small components. However, they play a significant role in keeping you safe while driving. If the wheels are not secured to the vehicle correctly, the results can range from wheel or fastener damage to catastrophic failure.

This article briefly discusses what’s the proper length of your wheel bolts. Note that a standard wheel bolt can split into two parts: the shank part and the threaded part. The shank is the threadless part of the bolt between the head and thread. And the threaded parts are usually machined with different thread diameters. The sum of the lengths of the two parts is the length of the wheel bolts.

How to Determine the Correct Wheel Bolts Length?

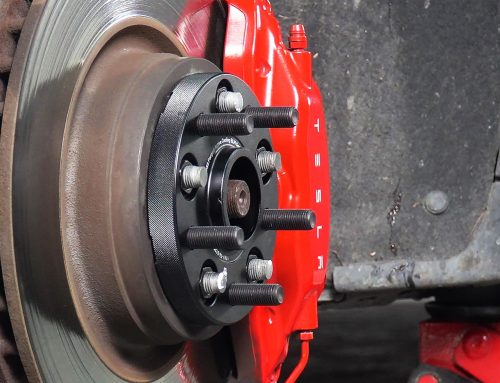

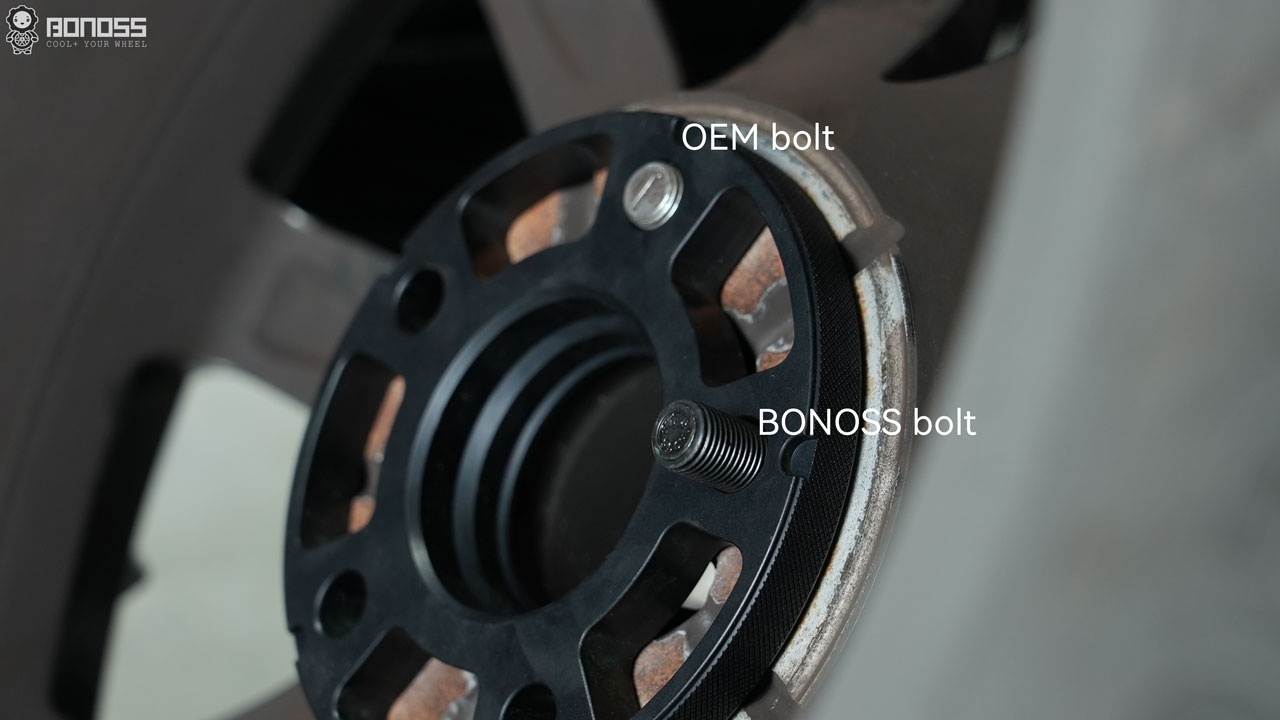

You’ll need to re-measure the wheel bolts unless the suppliers specifically mentioned that you can use OEM wheel bolts to secure the new wheels. This is because some wheels have a thicker mounting pad (the surface where the bolt makes contact with the wheel). Besides, if you add wheel spacers, longer wheel bolts are always required. Here are some tips that may help you determine the correct wheel bolt length:

- Measure the length of your OEM wheel bolt. Assuming the stock bolt length is 29mm;

- Slide the stock bolt into one of the OEM wheels. Then measure the exposed thread stem on the back side of the wheel. Assuming you get 17mm exposed thread length;

- Slide the same stock bolt into one of the new wheels. If you add wheel spacers, mount a spacer on the wheel. Then measure the exposed thread stem on the back side of the wheel. Assuming you get a 5mm exposed thread length.

Example:

17mm – 5mm = 12mm, 29mm + 12mm = 41mm. You will need 41mm wheel bolts in order to properly secure the new wheels to the vehicle hub.

What Wheel Bolts Do I Need?

Wheel bolts often rely on axial force causing sufficient friction for the threads to remain in place. In other words, they apply a clamping force to keep everything in place. To improve driving safety, you absolutely need high-strength wheel bolts. ISO grade 12.9 wheel bolts are the strongest bolts that we have covered in the automotive world. A grade 12.9 marking means the tensile strength of this wheel bolt has reached 1,220 MPa.

Most OEM wheel bolts are grade 10.9 (about 1,040 MPa). The stronger the bolt is, the more force it can withstand more force before breaking. At the final step, tighten the wheel bolts a quarter turn at a time following the crisscross sequence (in a “star” pattern). This ensures that each bolt is forced evenly. Torquing each wheel bolt to the proper torque specification assures your new wheels and spacers are properly seated on the vehicle.