As long as you operate correctly and ensure a full thread engagement, cutting studs to fit wheel spacers won’t cause any problems. But how to cut wheel studs for spacers safely? Here is an example guide. The first step is to find out how much stud you should cut off. Measure the protruding OEM stud length and the wheel pocket depth. Use protruding OEM stud length subtract the wheel pocket depth to get the result value. For example, if the stock stud length is 27mm, and the wheel pocket depth is 10mm, then it is necessary to trim 2mm stud to fit a 15mm wheel spacer (27-15-10=2mm).

To ensure a proper fitment, cutting 3-4mm stock stud will be better. Mark 3-4mm stud length. Use an angle grinder or hack saw to cut in line with the marking, and clean up any burrs with a file to clean the threads up. Spray a little lube on the threads, screw in an open-end lug nut, and then remove it. That will help clean the threads you just cut. Always remember to get this project done in a reputable tire shop, or under the guidance of a professional, then you are good to go.

How to Choose the Best Wheel Spacers?

If you have ever checked the studs that are pressed in the wheel spacers, you would find that there are different head shapes. Generally, wheel studs with semi-circular or elliptical heads are found on most cheap casting wheel spacers. The material of cheap spacer is not dense enough and is relatively soft. When under high temperature and stress, the studs will loosen and spin if they cannot be fastened. This causes safety issues. That is why most cheap casting wheel spacers often use semi-circular or oval-shaped studs to prevent loosening.

Brands that focus on quality and performance are very strict in raw materials and manufacturing processes. BONOSS forged active cooling wheel spacers are made of high-strength forged 6061-T6 and 7075-T6 aluminum alloy materials. Undergone up to 3000 tons of pressure, the forging process makes them integrity structural, more durable, and more resistant to corrosion and oxidation. So, the wheel studs of BONOSS forged active cooling wheel spacers are whole round heads. They are firmly pressed in the spacers. You don’t need to worry about any loose issues.

What Makes BONOSS Wheel Spacers Safer?

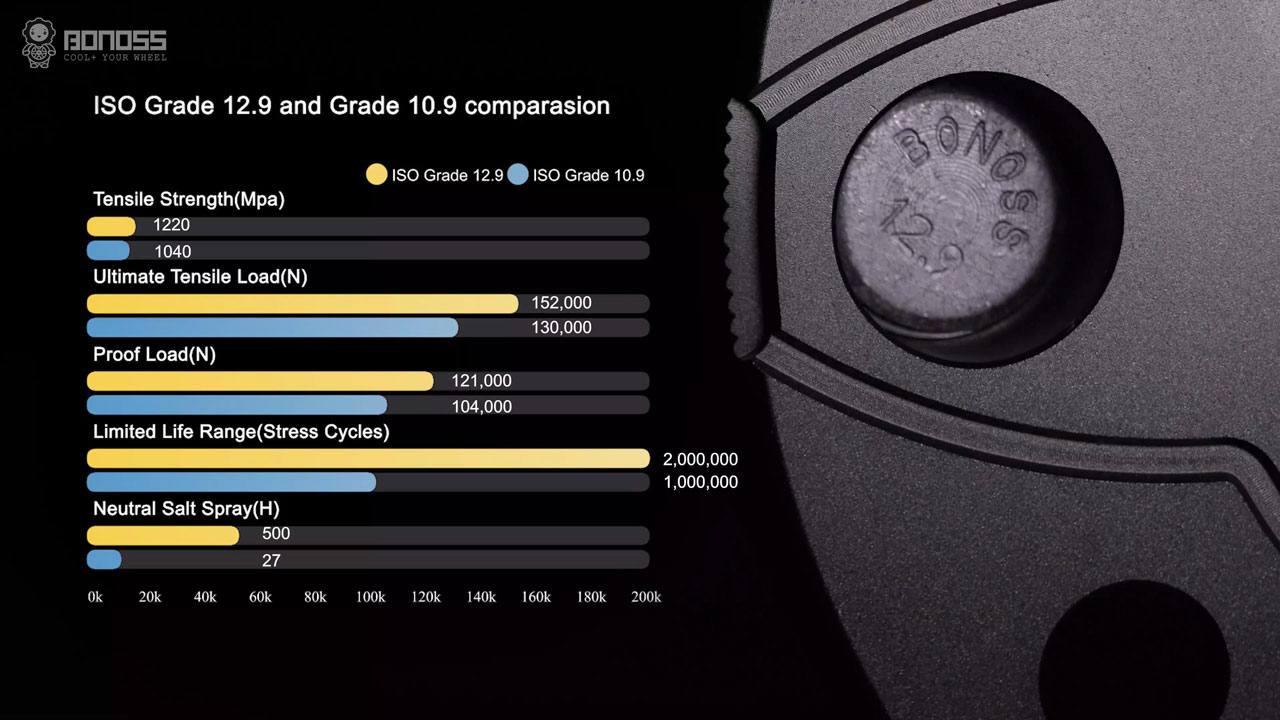

BONOSS provides ISO grade 12.9 wheel studs and ISO grade 10 wheel nuts to ensure a strong wheel-spacer-hub connection. The provided spacer wheel studs have achieved ISO standard grade 12.9, tensile strength≥ 1,220 MPa, ultimate tensile load ≥ 152,000 N, hardness (HV) ≥ 395, and NSS ≥ 500H. Additionally, BONOSS forged active cooling wheel spacers come with full-cone lug seats. Full-cone seat design allows the studs and nuts to apply enough clamping force to lock the spacers, avoiding any potential loosening risks.

Particularly, the provided wheel studs and lug nuts applied the superior Dacromet surface treatment process. This type of coating gives neutral salt spray resistances exceeding 500 hours. Most importantly, Dacromet coating does not induce Hydrogen Embrittlement, which means that high-tensile components like wheel studs and lug nuts can be safely coated. It is an excellent surface treatment of connection elements and safety components in automotive components and accessories. So, it is a good idea to upgrade your car with BONOSS forged active cooling wheel spacers.