Wheel spacers are used for various reasons. When the offset of wheels is insufficient, wheel spacers would make up the desired offset by pushing the wheels away from the vehicle hub. Having your wheel brought out the ideal distance allows for mounting larger brake calipers without wheel scratching. Hub-centric wheel spacers can make a snug connection between wheel and axle hub, transforming a lug-centric wheel into a hub-centric wheel, meaning elimination of high-speed vibration. For decoration reasons, wheel spacers give your car a more aggressive exterior as well as a better aerodynamics body. The main manufacturing processes of wheel spacers on the market are forging and casting. Even with the same material, wheel spacers behave with different mechanical performances by different processes.

Forged aluminum alloy wheel spacers are manufactured from a solid piece of billets. They have undergone continuous intense pressure to be formed. Particularly, forged wheel spacers are one-piece wheel spacers. Due to the continuous stress cycle and process of deformation, the forged wheel spacers become hard and tough. The strength is greatly enhanced. Consistent forging allows achieving the same structural integrity with less material in comparison to cast wheel spacers. Besides, considering the strength of equipment needed to manufacture forged wheel spacers, this type of wheel spacers is stronger than cast wheel spacers.

Any cast aluminum spacer is a mixture of molten aluminum alloy. It is poured into a specific mold where it acquires its final shape with the help of a vacuum. When it is cooled, it is possible to make modifications like drilling or trimming. Casting wheel spacers are considered to be quick and inexpensive in terms of manufacturing. However, the major defect can’t be avoided- the nature of its manufacturing results in the occurrence of porosity. In addition, since it is not manufactured with the same structural integrity continuously (form transformation occurs), its mechanical properties are not as good as forging.

Any cast aluminum spacer is a mixture of molten aluminum alloy. It is poured into a specific mold where it acquires its final shape with the help of a vacuum. When it is cooled, it is possible to make modifications like drilling or trimming. Casting wheel spacers are considered to be quick and inexpensive in terms of manufacturing. However, the major defect can’t be avoided- the nature of its manufacturing results in the occurrence of porosity. In addition, since it is not manufactured with the same structural integrity continuously (form transformation occurs), its mechanical properties are not as good as forging.

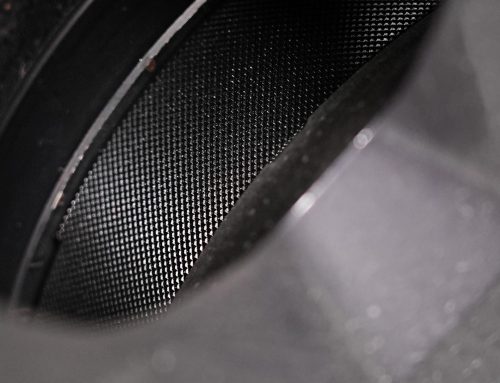

Here is a scrap comparison:

In the photo above, the casting Aluminum scrap is soft and granular, which will break easily if stretched long enough. It is because the casting wheel spacer is not manufactured with the same structural integrity continuously (form transformation occurs), its mechanical properties are not as good as forging.

In the photo above, the forged Aluminum scrap is slender and slim, which can be stretched very long without breaking. It is because the toughness property of forged wheel spacer is good. This is persuasive evidence of precise manufacturing and the high toughness of forged Aluminum.

Many off-road vehicle owners use wheel spacers to widen the track width and gain stability while rock crawling. Considering the requirements of strength, then casting wheel spacers would not be suitable anymore. Most cheap spacers are made from low-grade aluminum. These low-quality casting spacers are not strong enough and will be deformed and destroyed under intense impacts, leading to disasters. In opposite, forged spacers which are machined from billet aluminum (aircraft grade), are quite stronger and higher performance than their cast alternatives. If you need spacers, we recommend you purchase the highest quality ones available to reduce the risk of failure. Some people find that cast wheel spacers are much cheaper than forged ones. That’s because forging takes longer and costs more than casting. You get what you pay for. The actual performance of forged wheel spacers worth the price. Pick out the right spacers and you will have confidence each time you drive on the field to enjoy the pleasure of off-road adventure.