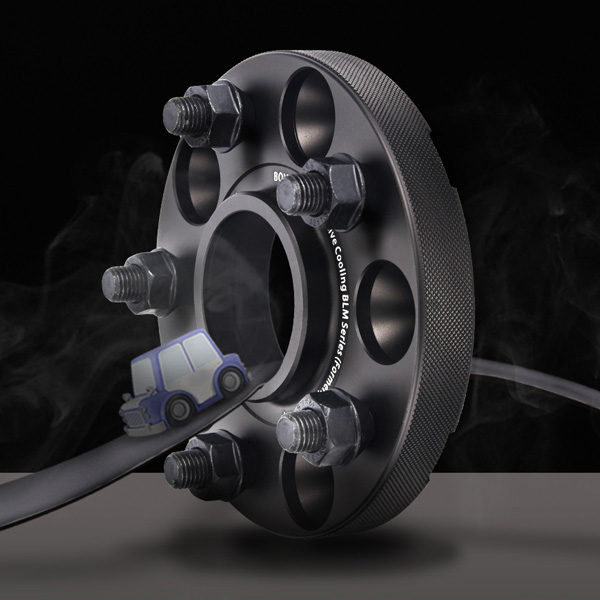

In BONOSS BLM Series Wheel Spacers, there are matching lug studs and nuts which are specific designed to fit the spacers as well as the wheels. This can not only make it easier to mount wheels without having to hold the wheel up to align the holes, but also make it perfectly suit the vehicle hub. The wheels are mounted using lug nuts, which are screwed onto the stud. This also allows you to install some really nice style of lug nuts.

JIS SCM440 High-strength Steel Material

The matching wheel studs applied JIS SCM440 steel material. The SCM440 is a medium carbon chromium molybdenum alloy steel. The Chromium provides good hardness permeability and Molybdenum gives hardness uniformity and high strength. It also has good ductility and high-temperature stress resistance, structural stability, low harmful elements, small decarburization layer, few surface defects and more advantages. Wheel Bolts made of Forged SCM440 alloy steel features many desirable properties such as high strength, wear-resistance, excellent toughness, impact resistance and high-temperature resistance.

| Grade 12.9 Matching Studs & Grade 10 Nuts | |

|---|---|

| Tensile Strength | 1220MPa (Test Method: ISO 898) |

| Ultimate Tensile Load | 152000N (Test Method: ISO 898) |

| Proof Load | 121000N (Test Method: ISO 898) |

| Hardness(HV) | 395 (Test Method: ISO 6507) |

| Wedge Loading Angle | 4 ° (Test Method: ISO 898) |

| Limited Life Range Test | 2000000 Stress Cycles Without Damage (ISO 3800) |

| Neutral Salt Spray Test | 500H (Test Method: ISO 9227) |

Great Dacromet Surface Treatment

The matching studs/nuts of BONOSS wheel spacers applied the superior Dacromet Surface Treatment process. Dacromet is a new type of metal surface anti-corrosion coating that uses aluminum flakes, zinc and chromic acid as the main coating materials. Here are the advantages of the Dacromet Surface Treatment:

1. No hydrogen embrittlement, so that it is very suitable for the coating of the force components like wheel studs and lug nuts.

2. High corrosion resistance. It is 7-10 times better than traditional galvanizing treatment. The neutral salt spray test can last for more than 500 hours and even higher, which is far better than galvanized.

3. Heat resistance. The Dacromet coating has a heat resistance temperature of above 300 ° C. It can also be used continuously for a long time at 250 ° C. At that temperature, the zinc layer has already been failed.

4. Excellent permeability. The Dacromet treatment fluid can penetrate into the tight joint of the workpiece to form a rust-proof coating so that it can improve the rust prevention ability inside and outside. In addition, it behaves greatly at the assembly of parts and at multiple screwing.

5. Environmentally Friendly. It is an environment-friendly coating process. During the technical treatment of Dacromet, there is no acid washing, electrodeposition, electric de-oiling, etc. That means no pollution.

The Dacromet surface treatment offers excellent protection for wheel studs and lug nuts. And because of the general avoidance of hydrogen embrittlement, it is an excellent choice for the coating of connection elements and safety components in the automotive components and accessories.