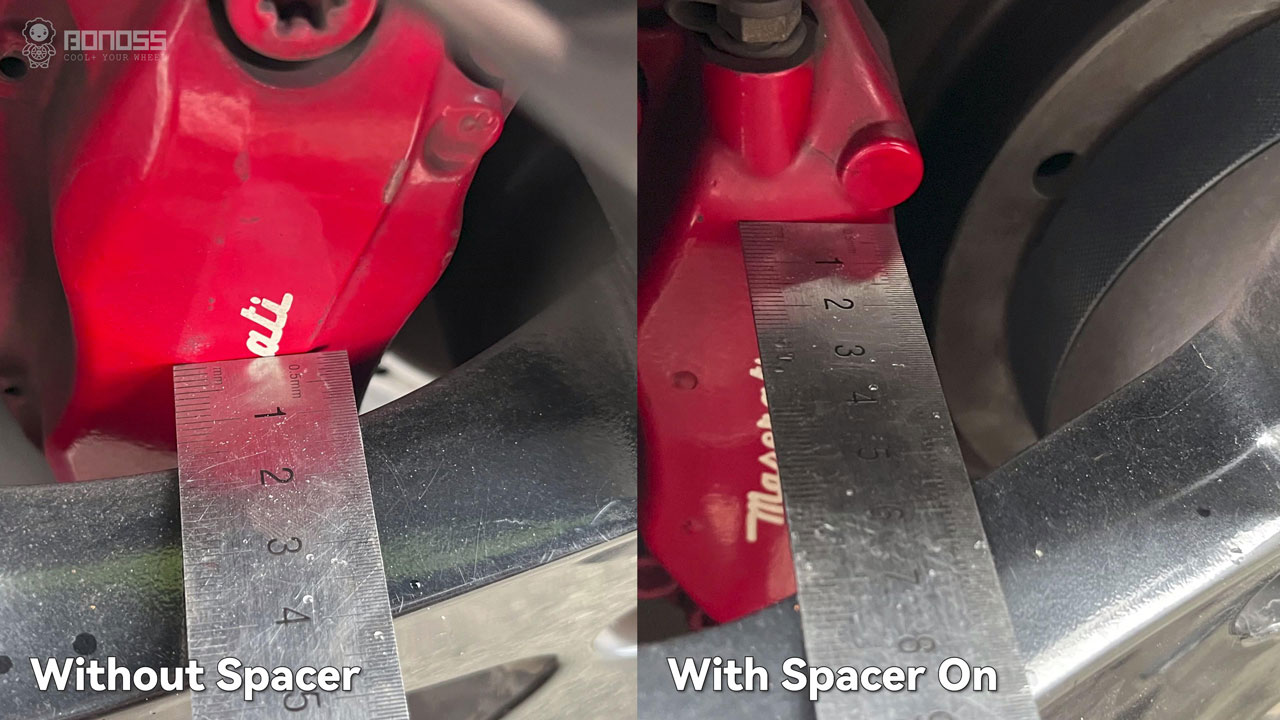

Wheel spacers provide many practical benefits. The best one is the extra distance they create between the wheels and the brake rotors. This is particularly important for those who need that extra space to clear big-size brake calipers. Because higher-performance brake calipers are often bigger than the stock parts. To ensure a safe wheel rotation, you would need at least 3mm in all directions from the wheel to the caliper. In this case, the wheel spacers prevent those large brake calipers from exceeding the inside wheel spokes.

In other words, adding wheel spacers allows you to install a larger performance brake kit without rubbing against the wheel spokes. Even if you don’t change stock rims or tires, these wheel spacers add more space for the wheels to maneuver, causing the tires to be further apart from each other. Increasing the track width results in more stability and smoothness. It turns out that installing spacers is one of the easiest and quickest ways to improve handling characteristics.

What Types of Wheel Spacers Are Best for Brakes?

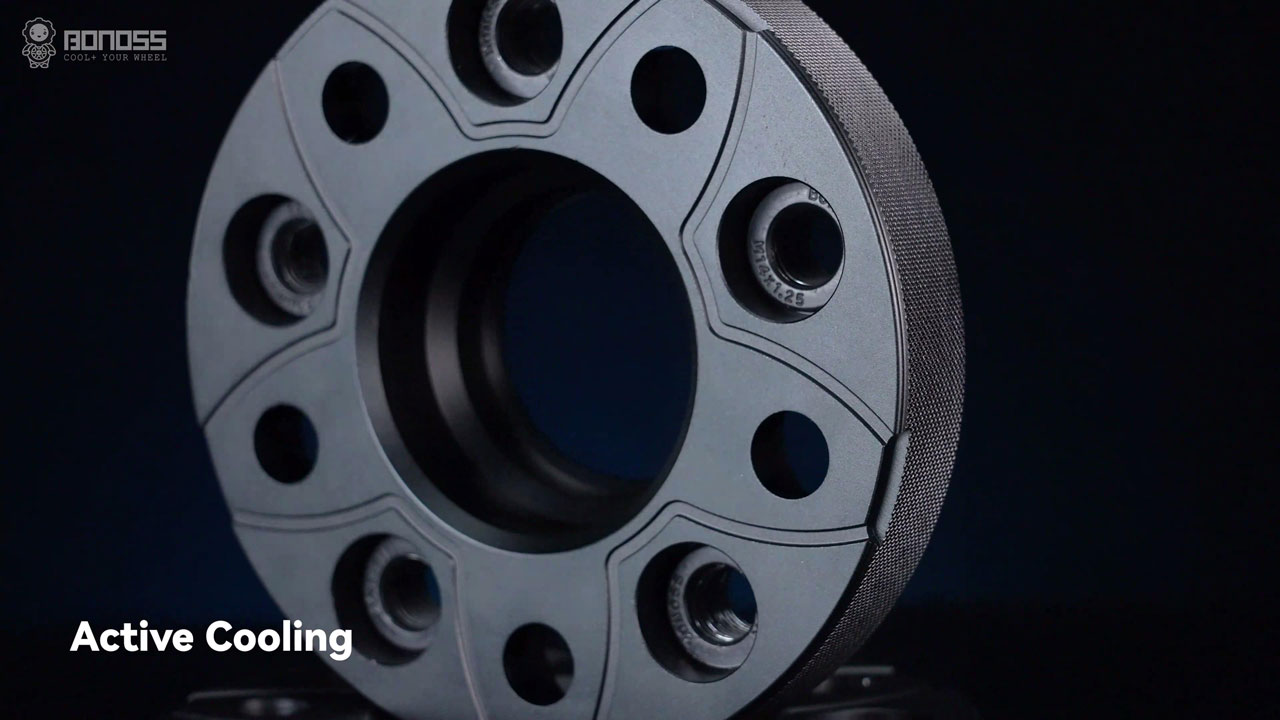

With these wheel spacers, there is nothing that physically stops the size of the modification. When choosing quality spacers for performance upgrades, aluminum types come as a priority. BONOSS forged active cooling wheel spacers are made of forged 6061-T6 and 7075-T6 aluminum alloys. The tensile strength is up to 572 MPa (AL7075-T6). Because of good thermal conductivity, the aluminum alloy rim spacers will dissipate brake heat better. This is exactly good for your new aftermarket brakes.

Apart from the base functions of spacers, BONOSS forged active cooling wheel spacers provide more practical features. For example, the active cooling function. Distributed in petal shape, these heat dissipation grooves allow the external cold air to flow continuously inside the wheel spacer when it rotates. The air takes away the heat, so it achieves the purpose of actively dissipating heat for the braking system. These BONOSS forged active cooling wheel spacers are helpful in making brake cooling better.

Is It Hard to Remove Wheel Spacers?

Removing wheel spacers isn’t hard. However, if you use Loctite on the wheel spacers, things may be a little troublesome when you intend to remove the wheel spacers for routine maintenance. Actually, it is optional to use Loctite on spacers. The threadlocker will glue the studs and nuts together. It makes the removal process hard. Normally, it is not necessary to use Loctite on BONOSS wheel spacers. Because BONOSS forged active cooling wheel spacers come with ISO grade 12.9 wheel studs and ISO grade 10 wheel nuts. They are meticulously coated with Dacromet.

The Dacromet coating provides four-way corrosion protection for those wheel lugs. What’s better, BONOSS forged active cooling wheel spacers come with disassembly grooves. The disassembly grooves refer to the small notches that are distributed on the corner of wheel spacers. Normally, a notch leaves a limited clearance between the brake rotor and the spacer. When removing these BONOSS forged active cooling wheel spacers, get a flat-head screwdriver and place it on one notch. Pound a hammer on the screwdriver at a 45-degree angle. It should come off pretty easily.