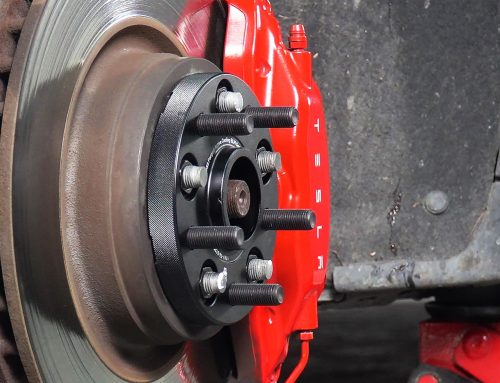

Lug nuts are fasteners that are used to secure the wheels on a vehicle. They are threaded to the wheel studs on the vehicle’s axle, locking the wheels in place and centering them properly on the hub assembly. Typically, they are found on most American-made and Asian-made cars. When replacing the rims, people end up purchasing new nuts to fit the wheel lug seats. In fact, a set of new lug nuts is cost-effective insurance for tire and wheel safety.

Since aftermarket lug nuts are made by different manufacturers, there are various options. Choosing the right set will make your time and money worthwhile. High-quality wheel nuts provide a better installing experience as well as good performance. If you would like to improve the appearance of your wheels, there’s nothing better than a new set of aftermarket good wheel nuts.

Are ISO Grade 10 Steel Lug Nuts Better?

Lug nuts are made of different grades of steel. Most wheel lug nuts express performance in metric grades. There are two common metric grades: 8 and 10. Each grade has a specific nut strength. The higher number means the higher the tensile strength of the lug nut. The minimum proof load of grade 10 lug nuts is 1100MPa which is far exceeds the standard grade 8. Since tensile strength is the amount of force the nut can withstand before breaking, changing to higher grade lug nuts improves safety. All BONOSS steel lug nuts are ISO grade 10. For most automotive applications, you will need at least metric grade 8 nuts. However, grade 10 lug nuts are much better and safer. Before purchasing a new set of wheel nuts, check the grade first.

Are Aluminum Lug Nuts Good?

Forged aluminum lug nuts perform better than other lug nuts in some aspects. The forging process eliminates the porosity, ensuring structural integrity. This makes them not easy to break. The continuous forging process adds superior mechanical and physical properties created by heat and pressure. They are higher strength than those cheap casting ones. The best part is Aluminum wheel nuts are lightweight with exceptional strength. Reducing unsprung weight is an important advantage for increasing acceleration capability. Due to the properties of aluminum alloys, they are protected by their own naturally occurring oxide film, which brings them incredibly resistant to corrosion.

In addition, aluminum alloy features good finishing characteristics and responds well to anodizing. Therefore, aluminum lug nuts are able to be anodized in a variety of colors, such as red, black, blue, grey, etc. Normally, color matching will essentially improve your design’s visual appeal. Applying aluminum lug nuts of the correct colors would make your wheels look outstanding and fashionable.