When it comes to bolt-on wheel spacers, there are lug holes. The wheel bolts go through these lug holes, securing the spacers onto the hub assembly. This means there may be different seat types that existed. Failure to use the proper lugs bolts may cause your vehicle to vibrate and could cause the wheel bolts to loosen over time. Most bolt-on wheel spacers are equipped with the correct wheel bolts to fit. So, let’s leave the wheel bolts aside, and focus on the lug seats of the wheel spacers.

Most wheel spacers are machined with conical lug seats. However, there are different kinds of conical seats, the most common types are full-cone seats and part-cone seats. In a brief word, a full-cone seat is a proven upgrade of a part-cone seat. With full-cone seat wheel spacers, the wheel bolts can fully contact the spacers. This allows the bolts to apply enough clamping force to lock the spacers, avoiding any potential loosening risks.

Full-cone Seat or Part-cone Seat Wheel Spacers

It is always a good idea to keep wheel bolts fully in contacting the spacers, which would require the full-cone lug seats. Proper tightening is critical insurance for the hub-spacer-wheel connection. Full-cone lug seats are the same 60-degree angle and contact area proportion as most BMW OEM wheels bolts are. They provide a larger contact area, more force acreage, and better fitting. In these cases, the wheel spacers can be fastened firmly, meaning no vibration, fewer stress loads, higher safety, and a longer service life range.

On the other hand, a part-cone lug seat is designed with a narrow contact area, which is half of a normal cone seat. Unfortunately, most cheap wheel spacers are made in bulk and as quickly as possible. For cost-saving, most of them are part-cone lug seats. Compared to the full-cone seat design, it offers a smaller contact area and less force acreage. Without a proper fastening, road impacts are more likely to deform the bolts, resulting in vibrations. Full-cone seat wheel spacers not only bring a better-installing experience but also more particularly guarantee safety.

Semi-circular, Elliptical, or Round Wheel Bolts Heads

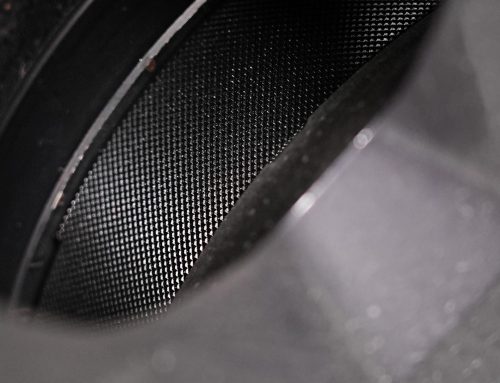

If you have ever checked the studs that are pressed in the wheel spacers, you would find that there are different head shapes. Commonly, there are three shapes: semi-circular, elliptical, and round. Generally, wheel studs with semi-circular or elliptical heads are found on most cheap casting wheel spacers. The material of cheap spacer is not dense enough and is relatively soft. When under high temperature and stress, the studs will loosen and spin if they cannot be fastened. This causes safety issues. That is why most cheap casting wheel spacers often use semi-circular or oval-shaped bolts to prevent loosening.

Brands that focus on quality and performance are very strict in raw materials and manufacturing processes. BONOSS wheel spacers are made of high-strength 6061-T6 and 7075-T6 aluminum alloy materials. Undergone up to 3000 tons of pressure, the forging process makes them integrity in structural, more durable, and more resistant to corrosion and oxidation. So, the wheel studs of BONOSS wheel spacers are whole round heads. They are firmly pressed in the spacers. You don’t need to worry about any loosen issues.