A few days ago, Mercedes-Benz has released the new 2022 W206-generation C300 Sedan. With a more aggressive look, sporty cabin, and technologically-sense interior tech, this C-Class has become more exquisite and powerful. Many car owners would like to install wheel spacers for a more stable cornering performance and a better stance or to make wheels fit bigger brake calipers and correct the wrong offset. Since the wheels are the parts that bear the most stress (wear and tear) along with the bottom bracket, the quality of spacers will be extremely important. What kind of wheel spacers are safe wheel spacers? Here we go through these essential specifications: material, precision, strength, design…

Premium Material for Wheel Spacers Safe

It is easy to notice that there are wheel spacers of different materials that exist on the market. When choosing safe wheel spacers, material selection can be very important. Since quality is a crucial part of wheel spacer safety, BONOSS only uses high-grade forged 6061-T6 or 7075-T6 billet aluminum alloy material for higher performance and safety. Both 6061-T6 and 7075-T6 are high-performance Aluminum Alloys. They feature good corrosion resistance, weldability, workability, and machinability. After the forged process, the structural strength, toughness, and corrosion resistance are improved greatly. In addition, the tensile strength of 7075-T6 is nearly double that of 6061-T6. The hardness of 7075-T6 is about 1.5 times that of 6061-T6. Both forged 6061-T6 and forged 7075-T6 wheel spacers are available in BONOSS Stock.

| Model | Tensile Strength | Yield Strength | Failure Elongation |

|---|---|---|---|

| 6061 | 18,000 psi (125 Mpa) | 8,000 psi (55 Mpa) | 25-30% |

| 6061-T6 | 42,000-45,000 psi (300-310 Mpa) | 35,000-40,000 psi (241-275 Mpa) | 8-10% |

| 6082 | 19,000 psi (130 Mpa) | 12,000 psi (85 Mpa) | 27% |

| 6082-T6 | 49,000 psi (340 Mpa) | 30,000-42,000 psi (210-290 Mpa) | 6-11% |

| 7075 | 40,000 psi (276 Mpa) | 21,000 psi (145 Mpa) | 9-11% |

| 7075-T6 | 74,000-78,000 psi (510-572 Mpa) | 63,000-69000 psi (434-503 Mpa) | 5-11% |

Data Sources: Wikipedia, aalco…

High Precision for Better Surface Quality

Precision, which is one of the most important indicators of wheel spacers quality, has become the core part of verifying the production level of a manufacturing enterprise. At BONOSS, we have achieved precision control at 0.02mm. The parallelism, perpendicularity, and coaxiality have been reached to the optimal degree of the process. Producing wheel spacers with such precision can not only ensure high quality and safety but also reduce waste, improve economic efficiency, meanwhile, more environmentally-friendly. In addition, they offer a smooth installation experience.

Strong Strength to Keep Safety

Any time you run wheel spacers, extended wheel bolts are necessary components. As a crucial part of locking the wheels, the strength of extended lug bolts is very important. BONOSS Forged Grade 12.9 Extended Wheel Bolts applied JIS SCM440 steel material. The JIS SCM440 steel is a medium carbon chromium molybdenum alloy steel, which provides good hardness permeability, hardness uniformity, and high strength. It also has good ductility and high-temperature stress resistance, structural stability, low harmful elements, small decarburization layer, few surface defects and more advantages. Wheel Bolts made of forged SCM440 alloy steel features many desirable properties such as high strength, wear-resistance, excellent toughness, impact resistance and high-temperature resistance. Compared to some cheap casting steel lug wheel bolts, they offer higher strength as well as higher safety.

Elaborate Design for Higher Performance

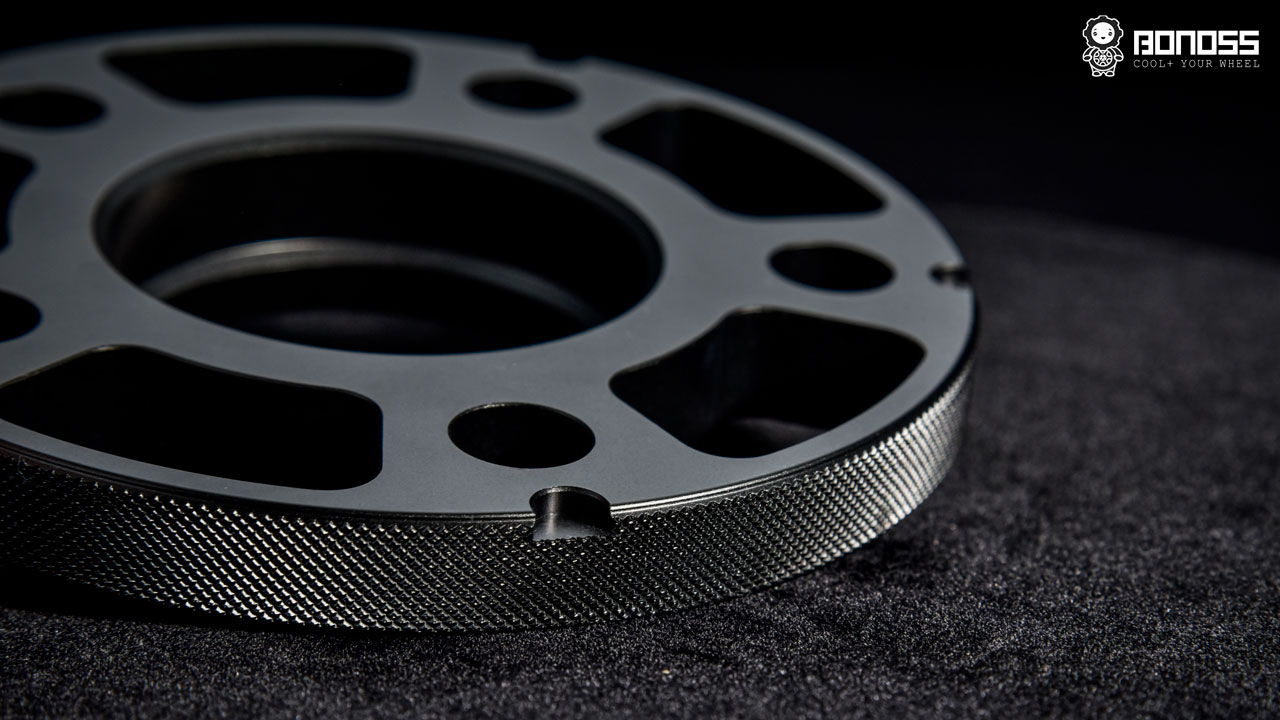

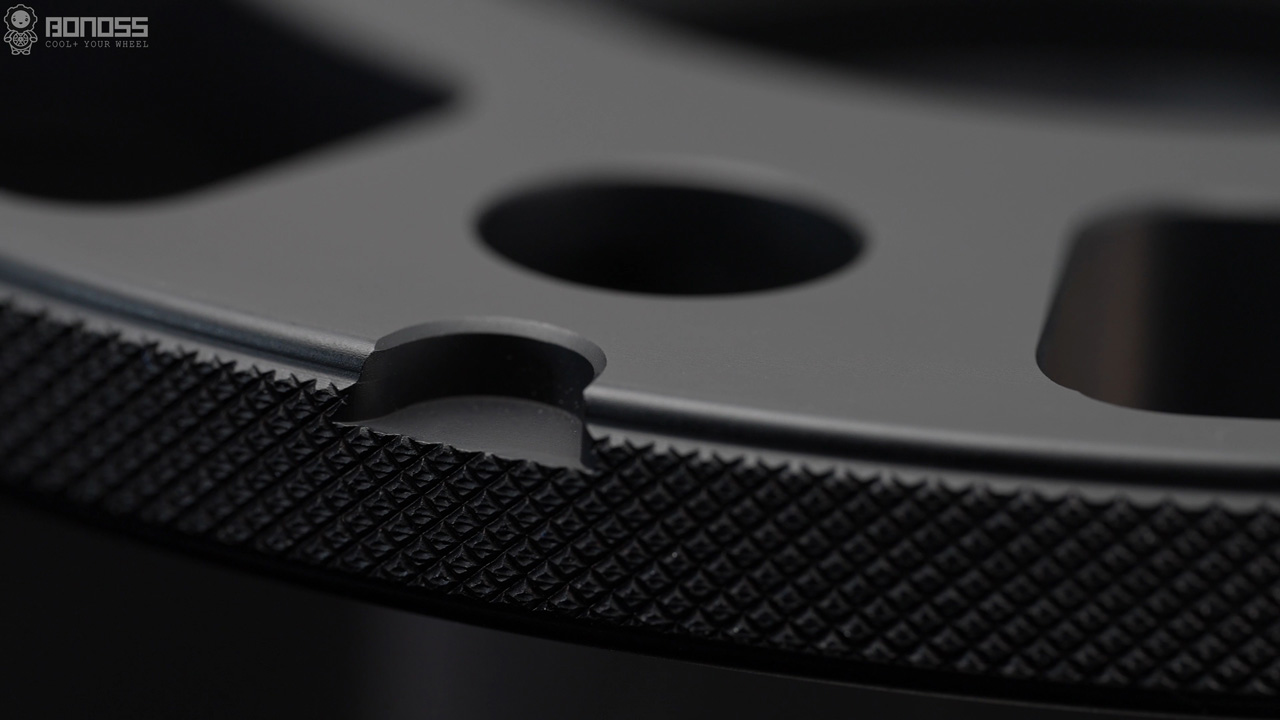

Whether a spacer is well-designed is a central standard to distinguish the quality of the spacer. In the marketplace, there are a lot of wheel spacers that copy the same design, which is called universal wheel spacers. You can install these spacers, but the experience may not satisfactory. That is why BONOSS insists on independent design for products. BONOSS Forged Lightweight Plus Wheel Spacers are well-engineered for fitting your Mercedes-Benz C300 W206. Lighter is better, theoretically, reducing unsprung weight helps a car’s suspension system work more effectively. The “Lightweight Plus” design of BONOSS Wheel Spacers means the further optimized hollow design for lightweight, based on the traditional wheel spacers. It is a proven design that is effectively reducing weight, reducing energy consumption, improving control performance, and achieving a balance between high performance and environmental protection on the premise of ensuring safety and reliability. Besides, the special disassembly grooves, side knurling design, and sealed design make BONOSS wheel spacers higher performance, better surface quality, more functions than other competitors.

In Summary

In most cases, car manufacturers will leave contain space for tire chains. Wheel spacers push your existing wheels out more to fill the wheel-wells or your custom wide-body fenders properly. They also give your car better cornering, aerodynamics, and look. However, every vehicle is distinct, sometimes even from the front to the rear wheels, so please carefully check each item for safe installation. Know the precise data and choose the right one, you will be happy for a while.