Wheel spacers are sandwiched between the assembly hub and wheel. The wheel lugs apply a clamping force to secure the spacer and wheel to the vehicle hub. When the lug nuts are properly tightened, the wheel studs will stretch elastically (like very stiff springs) to keep everything in the right place. The common myth is that wheel spacers wreck the physics of the wheels and wheel hubs. This is actually incorrect because installing a wheel spacer between the hub and wheel will not change these physics. As long as you use high-quality spacers and install them properly to prevent flexing and loss of clamp force, wheel spacers are a very safe mod for your vehicle.

Most of the disadvantages that people associate with wheel spacers are actually blamed on the low-quality spacers and improper installation. Most cheap spacers are made from low-grade casting aluminum. These low-quality casting spacers are not strong enough and will be deformed and destroyed under intense impacts, leading to disasters. And improper installation, for example, untightened or overtightened lug nuts will also increase the chances of accidents.

Important Concerns for Wheel Spacers Safe

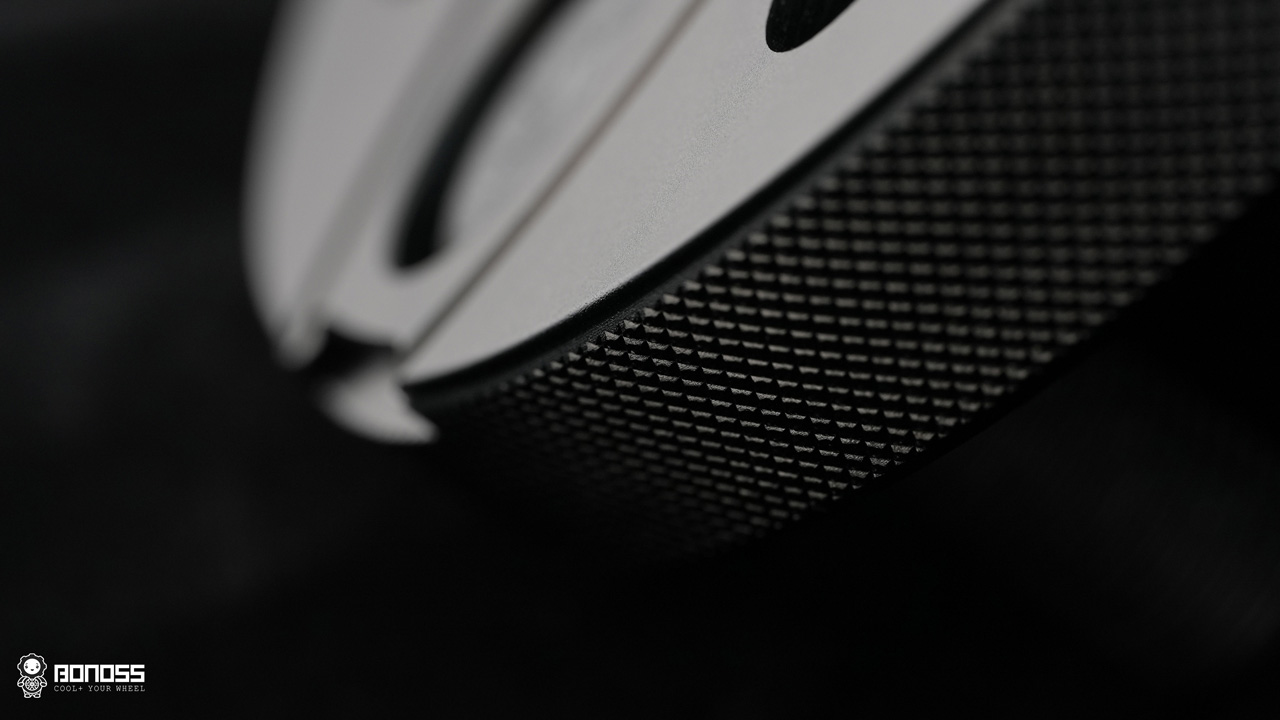

We understand that most vehicle owners are very concerned about the quality of the products they use on their vehicles. The quality is also a crucial part of wheel spacers safety. This is why we only use the highest quality materials. You don’t have to compromise on quality. BONOSS manufactures wheel spacers and adapters in stock with high-grade forged 6061-T6 and 7075-T6 billet aluminum alloy which both feature many desirable properties such as high strength, wear-resistance, excellent toughness, impact resistance and high-temperature resistance. And the forged manufacturing process further enhances the hardness and toughness of the spacers. Consistent forging allows achieving the same structural integrity with less material in comparison to cast wheel spacers. Besides, considering the strength of equipment needed to manufacture forged wheel spacers, this type of wheel spacers is stronger than cast wheel spacers. Besides, they are made with modern CNC machinery, precision to 0.02mm tolerance, ensuring that each wheel spacer or adapter fits snugly and securely, and is built to exact specifications.

Important Concerns for Wheel Spacers Installation

Typically, wheel spacers are exactly safe if they’re installed properly. But it is not recommended that you try installing them on your own, if you are not a professional or under the guidance of a Qualified Mechanic. The wheel spacers need to be installed correctly, and they also must be properly torqued to manufacturer-recommended torque specs. This means making sure the spacer, wheel, and hub are secured enough to where they don’t get loosen. Untightened lug nuts (the clamping force is not enough) or overtightened lug nuts (the stud has been stretched past its tensile strength limit, so the clamping force has gone away) will cause most lug stud failures. Find a suitable balance in the level of tightness and the stud will remain strong, providing the greatest possible force to keep the wheel attached to the hub. This ensures the wheel spacers safe.

In Summary

Spacers have existed for multiple decades, and as long as they are installed correctly, there is very little opportunity for failure. They have always been used widely, even within the highest level of racing events. People tend to be sensationalized on the internet, especially because they don’t want to admit that they have made mistakes in tightening the lug nuts or purchased cheap low-quality spacers. Therefore, properly installed high-quality wheel spacers are perfectly safe.