These photos come from Network or our customers, if there is any infringement, please contact us immediately to delete them.

Wheel spacers are sandwiched between the assembly hub and wheel. The wheel lugs apply a clamping force to secure the spacer and wheel to the vehicle hub. When the lug nuts are properly tightened, the wheel studs will stretch elastically (like very stiff springs) to keep everything in the right place. The common myth is that wheel spacers wreck the physics of the wheels and wheel hubs. This is actually incorrect because installing a wheel spacer between the hub and wheel will not change these physics. As long as you use high-quality spacers and install them properly to prevent flexing and loss of clamp force, wheel spacers are a very safe mod for your vehicle.

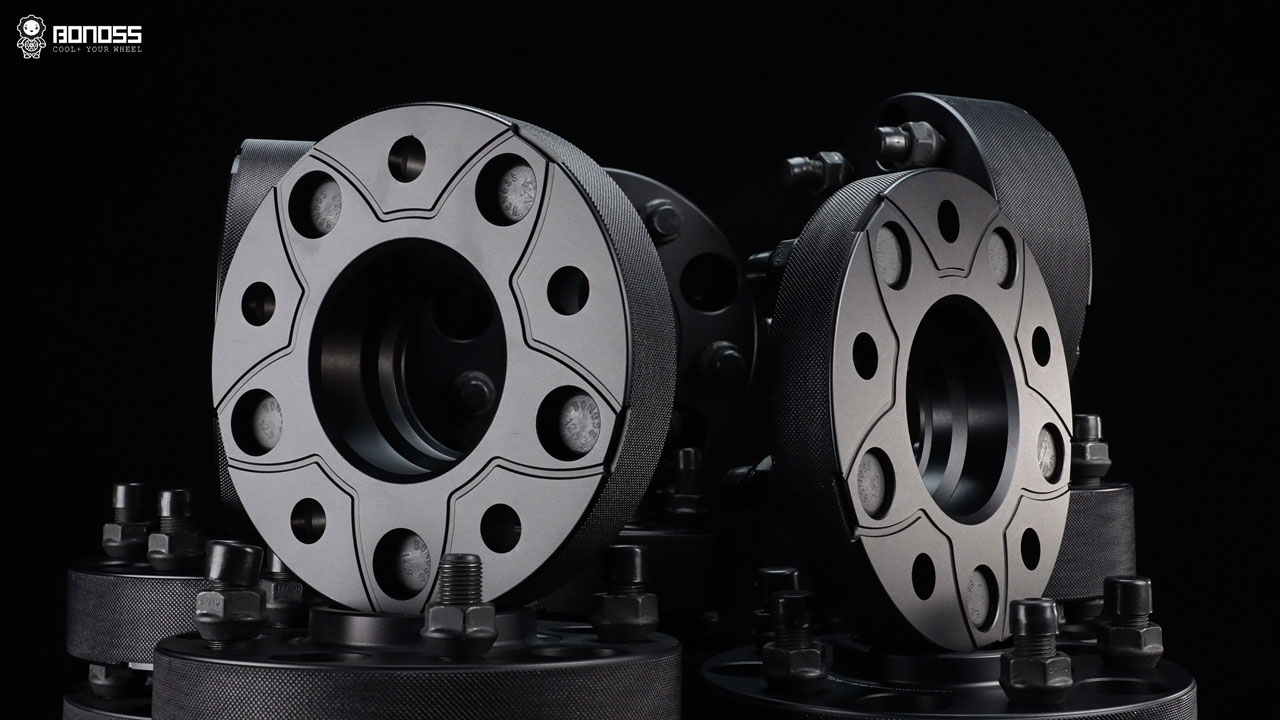

What are wheel spacers?

Wheel spacers are a kind of aftermarket wheel components. They’re a simple and inexpensive upgrade that provides many advantages to your vehicles. By pushing the wheel away an ideal distance from the hub, it creates spaces between the wheel and hub. If your new wheels set up do not have the proper offset, it will cause the wheel to rub against the internal suspension components. (Wheels will stick in too much). If you have upgraded your braking system with bigger calipers, it will take up spaces that cause the wheel cannot be mounted back properly. Installing wheel spacers or adapters can create extra clearance to push the wheels outward to correct the wrong offset as well as pass larger calipers for wheel fitment. They are also commonly used for handling improvement and visual enhancement. By spacing the wheels out, it will provide more stability and better corner control to the vehicle.

Hub-centric wheel spacers vs. Lug-centric wheel spacers

There are a lot of options you’ll find with wheel spacers, but they are mainly classified as hub-centric spacers and lug-centric spacers. We recommend hub-centric spacers rather than lug-centric spacers. Hub-centric spacers offer a better system of support and stability. They are designed to make a snug connection between the wheel and vehicle hub, ensuring the hub carries the weight of the car instead of the studs or bolts. Most of the disadvantages that people associate with wheel spacers are actually blamed to lug centric spacers. Due to non-hub centric design, there is a certain gap between the axle and the hub, which means that the wheel is centered by the lug studs rather than by the vehicle hub. Without firm contact, lacking the hub’s support, the studs play the role of bearing the road impacts. For some fierce impacts are strong enough to deform the studs, making the wheel no longer concentric with the hub, resulting in vibrations. Even worse, it may damage the wheel’s center bore.

Forged wheel spacers vs. Casting wheel spacers

Forged aluminum alloy wheel spacers are manufactured from a solid piece of billets. They have undergone continuous intense pressure to be formed. Particularly, forged wheel spacers are one-piece wheel spacers. Due to the continuous stress cycle and process of deformation, the forged wheel spacers become hard and tough. The strength is greatly enhanced. Consistent forging allows achieving the same structural integrity with less material in comparison to cast wheel spacers. Besides, considering the strength of equipment needed to manufacture forged wheel spacers, this type of wheel spacers is stronger than cast wheel spacers. Any cast aluminum spacer is a mixture of molten aluminum alloy. It is poured into a specific mold where it acquires its final shape with the help of a vacuum. When it is cooled, it is possible to make modifications like drilling or trimming. Casting wheel spacers are considered to be quick and inexpensive in terms of manufacturing. However, the major defect can’t be avoided- the nature of its manufacturing results in the occurrence of porosity. In addition, since it is not manufactured with the same structural integrity continuously (form transformation occurs), its mechanical properties are not as good as forging.