It is the intention of BONOSS to improve products continuously to offer a better experience. Under the hard efforts of our technical staff, we are proud to announce the born of “Active Cooling Wheel Spacers”. Active cooling wheel spacer, which added new practical features of heat dissipation, breaks through the limitation of traditional wheel spacers with a single function. That means buying such a wheel spacer can get all the base functions of spacers as well as more additional functions, but with a reasonable price. It is the first “active cooling” patented technology in the world. (BONOSS wheel spacers “active cooling” patented technology has registered with intellectual property institutions including the United States and the European Union since 2018.)

Heat Effects of Braking Performance

High heat will affect the performance of your brake system. One of the main reasons for heat creation in a braking system is to convert the engine stopping power into waste heat. The working principle of a braking system is to convert the kinetic energy of the vehicle into heat through friction. In that case, more friction and stopping power means higher heat. Of all various methods which are available to improve the performance of a braking system, heat dissipation ranks at the top level. The heat must be dispersed. If the brakes grow extremely hot, and the heat cannot escape from the brakes, your braking system will trend to damage, discounted performance, and finally leading to failure.

Advantages of Active Cooling Design

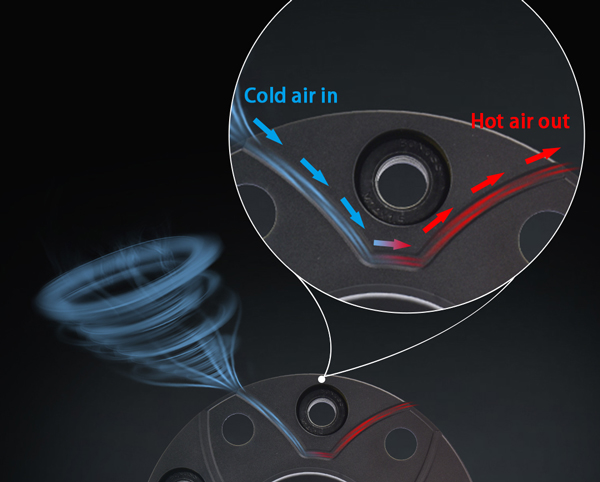

There is a specially designed heat dissipation grooves structure that exists on the active cooling wheel spacers. The grooves can make use of the wheel spacers rotation to allow the external cold air to flow efficiently and continuously inside the wheel spacers to take away the heat, so as to achieve the purpose of actively dissipating heat for the braking system. Through this way, it can improve braking efficiency, and reduce driving safety risks.

1. The grooves are distributed in petal shape, which allows multiple grooves to work at the same time, improving the heat dissipation efficiency greatly.

2. The grooves are designed with an aerodynamic arc, which is conducive to the rapid flow of air and further boosts the heat dissipation function.

3. The grooves are symmetrical design, no matter it is on the left or right wheel, whether driving forward or reversing, the purpose of heat dissipation can be normally and effectively achieved.

4. The grooves applied sealed design, not passing through the center hole, meaning it is capable to prevent rainwater or debris from entering the axle-spacer-wheel connection.

5. Each edge of the grooves is carved with funnel-shaped notches, acting as air collectors which tremendously enlarges the airflow, enhancing the heat dissipation effect.