Precision, which is one of the most important indicator of wheel spacers quality, has become the core part of verifying the production level of a manufacturing enterprise. At BONOSS, we have achieved precision control at 0.02mm. Producing wheel spacers with such precision can not only ensure high quality and safety but also reduce waste, improve economic efficiency, meanwhile, more environmentally-friendly. In addition, they offer a smooth installation experience.

Parallelism

Parallelism is a measurement of whether two planes of an item are parallel to each other, or whether two lines are parallel. In wheel spacers, parallelism means the parallelism degree of the upper and lower planes. Parallelism affects the degree of force transfer between wheel parts. The smaller the tolerance value, the higher the accuracy, the better the surface quality, the higher the reliability. It is very important for whether the spacers function properly.

Perpendicularity

Perpendicularity is a measurement of whether two surfaces of an object are perpendicular to each other, or whether two lines intersect at a right angle. In wheel spacers, perpendicularity means the perpendicular degree of the upper/lower planes and side planes. Perpendicularity affects the performance of force transmission between wheel parts. The higher the precision, the better the perpendicular degree, the better performance of bearing stress.

Coaxiality

Coaxiality is the tolerance for how exactly the central axis of one cylinder is to another. In wheel spacers, coaxiality means the coaxially degree of the centric rings and the PCD circle. Coaxiality conditions can be vital for shafts supporting heavy and varying loads, such as car and truck axles. High coaxiality ensures that the axle and the wheel are kept on the same centerline, meaning no additional force, no vibration, no annoying noise, less energy loss, less fatigue damage, longer service life.

Precision at Scrap

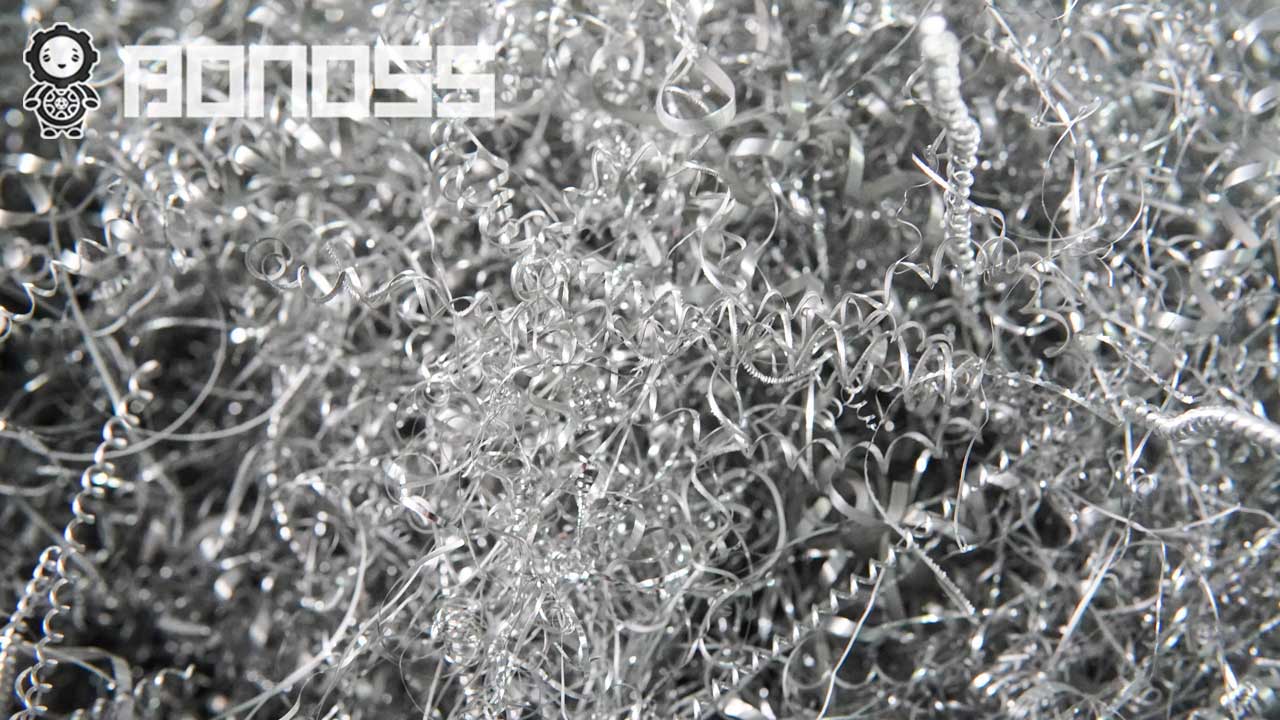

In the most basic sense, scrap means the excess material from manufacturing work. If a manufacturer producing a wheel spacer and has material leftover after finishing the spacer, that leftover material is considered scrap. However, scrap can not only be a complete batch of parts that needs to be recycled but also be an intuitive object which reflects the accuracy of processing. In the previous article, it has been mentioned that 6061-T6/7075-T6 Aluminum Alloy is high-performance metal. However, even the same material has different mechanical properties after different processing techniques. Compared with some cheap casting Aluminum, the forged one has substantially greater fracture toughness than the others. In addition to the relevant authority test report clearly pointed out, the scrap can also be strong evidence.

In the photo above, the casting Aluminum scrap is soft and granular, which will break easily if stretched long enough. It is because the casting wheel spacer is not manufactured the same structural integrity continuously (form transformation occurs), its mechanical properties are not as good as forging.

In the photo above, the forged Aluminum scrap is slender and slim, which can be stretched very long without breaking. It is because the forged wheel spacer undergoes continuous intense pressure to be formed. The toughness property is also greatly enhanced. This is a persuasive evidence of precise manufacturing and the high toughness of forged Aluminum.

Processing Equipment Capacity

As a matter of fact, the processing quality of a mechanical part largely comes from the processing accuracy of the production equipment. Precise processing means the process of cutting raw material to a very exacting specification. The process generally includes removing the excess from an object, reshaping it to a high-level tolerance end product. Precision machining is an essential manufacturing process in terms of achieving high surface integrity and dimensional accuracy of functional components. An advanced industrial manufacturer has a complete ability to produce high-precision products. Moreover, the enhancement of the machining accuracy of mechanical components effectively guarantees the safety, stability and reliability of the quality of wheel spacers, and ensures the smooth operation of vehicle wheel parts.

Environmentally Friendly

BONOSS has always paid great attention to environmental protection. One of the easiest ways to minimize scrap is to optimize the manufacturing process. The improvement of precision can not only provide high precision products but also reduce the scrap rate. Reducing unnecessary material waste means more environmentally friendly, more energy saving, more cost-saving, as a result, we can offer high-quality products but with more cost-effective prices for customers.